8×19 / 8×26 / 8×36 IWRC for Overhead Cranes

Main Applications

Overhead crane hoisting rope.

Rope Characteristics

Extremely flexible rope types with up to 288 single wires (8x36) in the outer strands. Better fatigue performance and fatigue life expectancy than 6x19/6x36. Due to the larger number of outer wires these ropes tend to be more sensitive to mechanical damages.

All 8-strand constructions require proper sheave- and drum groove dimensions. Undersized and/or worn sheaves will immediately result in rope deformations, waviness, or high strands. These ropes require extra care during installation (no reverse bend spooling).

Standard

ASTM 1023, Table 18, 19

8 x 19 Seale, Standard: EN 12385-4:2002 (8)

8 x 26 Warrington-Seale, Standard: EN 12385-4:2002 (8)

8 x 36 Warrington Seale, Standard: EN 12385-4:2002 (10)

ISO 2408

Breaking Strengths

Note: The maximum CAPACITY, WORKING LOAD LIMIT (WLL), or LINE PULL of the rope usually is 1/5 of the below stated values. For specific information consult the standards applicable to your rope application.

| Metric 8x19, 8x26, 8x36 IWRC (regular strength) | |||||

|---|---|---|---|---|---|

| Rope dia. mm | Construction | Lay | Tensile Strength N/mm2 | Minimum Breaking Strength kN | Weight per meter kg |

| 6.5 | 8x19 Seale | right | 2160 | 27.5 | 0.16 |

| 7 | 8x19 Seale | right | 2160 | 37.7 | 0.22 |

| 7.5 | 8x19 Seale | right & left | 2160 | 40.3 | 0.24 |

| 8 | 8x19 Seale | left | 1960 | 44.7 | 0.28 |

| 9 | 8x19 Seale | right & left | 1960 | 56.5 | 0.36 |

| 10 | 8x19 Seale | left | 1960 | 69.8 | 0.45 |

| 11 | 8x19 Seale | right & left | 1960 | 84.4 | 0.54 |

| 13 | 8x36 WS | right & left | 1960 | 118.0 | 0.75 |

| 14 | 8x26 WS | right & left | 1960 | 137.0 | 0.87 |

| 14 | 8x36 WS | right & left | 1960 | 137.0 | 0.87 |

| 16 | 8x26 WS | right & left | 2160 | 197.0 | 1.14 |

| 16 | 8x36 WS | right & left | 1960 | 179.0 | 1.14 |

| 18 | 8x36 WS | right | 1960 | 226.0 | 1.44 |

| 20 | 8x36 WS | right & left | 1960 | 279.0 | 1.78 |

| 24 | 8x36 WS | right & left | 1960 | 402.0 | 2.40 |

| 25 | 8x36 WS | right | 1960 | 459.0 | 2.87 |

| 26 | 8x36 WS | right | 1960 | 472.0 | 3.02 |

| 28 | 8x36 WS | right | 1960 | 547.0 | 3.27 |

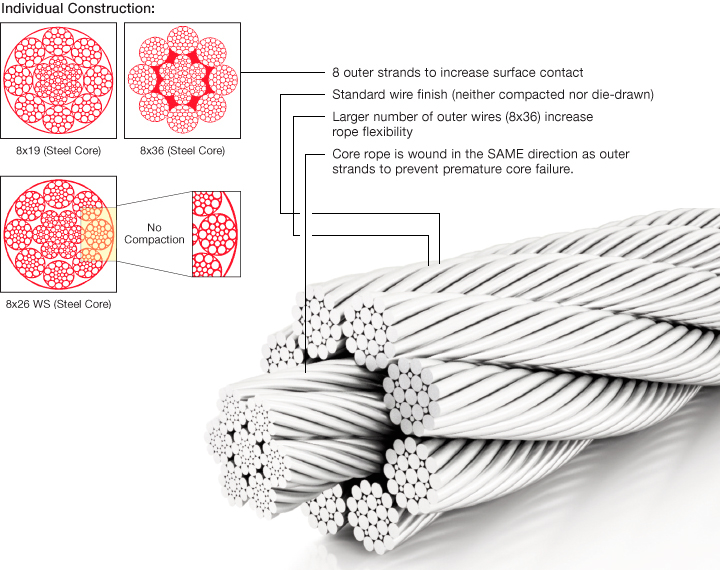

Standard Hoisting Rope for Overhead Cranes

Construction:

8×19 Seale

8×26 Warrington Seale

8×36 Warrington Seale