Maxibraid™

Rope Characteristics

Maxibraid is a 12-strand single-braid rope constructed from Ultra High Molecular Weight Polyethylene UHMWPE fiber. UHMWPE has the highest strength-to-weight ratio of any synthetic or natural fiber, and it floats. The integral Maxijacket High Performance coating firms the construction, increases wear life and helps keep contaminants out of the rope.

Maxibraid also has extremely low stretch and is laid firmer than Ultrex, sacrificing some tensile strength for longevity in tough field conditions. In many instances, we have found this firmer lay retains higher percentages of original breaking strength after use in the field for extended periods. Available in a variety of Maxijacket colors, which can help identify time in service, differentiate one rope from another or denote load ratings.

Breaking Strengths

| Diameter (Inches) |

Weight (Lbs/100f) |

Average Spliced Break Strength* (Lbs) |

Minimum Spliced Break Strength* (Lbs) |

Maximum Working Load 5:1** (Lbs) |

|---|---|---|---|---|

| 1/8 | 0.4 | 1,800 | 1,620 | 360 |

| 5/32 | 0.6 | 2,700 | 2,430 | 540 |

| 3/16 | 0.9 | 4,300 | 3,870 | 860 |

| 1/4 | 1.6 | 6,600 | 5,940 | 1,320 |

| 5/16 | 2.3 | 13,000 | 11,700 | 2,600 |

| 3/8 | 3.6 | 17,350 | 15,615 | 3,470 |

| 7/16 | 3.8 | 18,560 | 16,704 | 3,712 |

| 1/2 | 6.1 | 30,350 | 27,315 | 6,070 |

| 9/16 | 7.7 | 38,750 | 34,875 | 7,750 |

| 5/8 | 9.1 | 45,540 | 40,986 | 9,108 |

| 3/4 | 12.4 | 55,770 | 50,193 | 11,154 |

| 7/8 | 16.4 | 70,540 | 63,486 | 14,108 |

| 1 | 20.2 | 84,750 | 76,275 | 16,950 |

| 1-1/8 | 26.5 | 108,000 | 97,200 | 21,600 |

| 1-1/4 | 34.7 | 120,000 | 108,000 | 24,000 |

| 1-5/16 | 39.5 | 130,000 | 117,000 | 26,000 |

| 1-1/2 | 45.5 | 156,000 | 140,400 | 31,200 |

| 1-3/4 | 70.0 | 230,000 | 207,000 | 46,000 |

| 2 | 80.0 | 250,000 | 225,000 | 50,000 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

| Diameter (mm) |

Weight (Kg/100m) |

Average Spliced Break Strength* (kg) |

Minimum Spliced Break Strength* (kg) |

Maximum Working Load 5:1** (kg) |

|---|---|---|---|---|

| 3 | 0.4 | 815 | 734 | 163 |

| 4 | 0.6 | 1,225 | 1,103 | 245 |

| 5 | 0.9 | 1,950 | 1,755 | 390 |

| 6 | 1.6 | 2,995 | 2,696 | 599 |

| 8 | 2.3 | 5,900 | 5,310 | 1,180 |

| 10 | 3.6 | 7,875 | 7,088 | 1,575 |

| 11 | 3.8 | 8,425 | 7,583 | 1,685 |

| 13 | 6.1 | 13,775 | 12,398 | 2,755 |

| 14 | 7.7 | 17,590 | 15,831 | 3,518 |

| 16 | 9.1 | 20,675 | 18,608 | 4,135 |

| 19 | 12.4 | 25,315 | 22,784 | 5,063 |

| 22 | 16.4 | 32,025 | 28,823 | 6,405 |

| 25 | 20.2 | 38,475 | 34,628 | 7,695 |

| 29 | 26.5 | 49,030 | 44,127 | 9,806 |

| 32 | 34.7 | 54,480 | 49,032 | 10,896 |

| 33 | 39.5 | 59,020 | 53,118 | 11,804 |

| 38 | 45.5 | 70,820 | 63,738 | 14,164 |

| 44 | 70.0 | 104,420 | 93,978 | 20,884 |

| 51 | 80.0 | 113,500 | 102,150 | 22,700 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

Rope Details

Rope Benefits

|

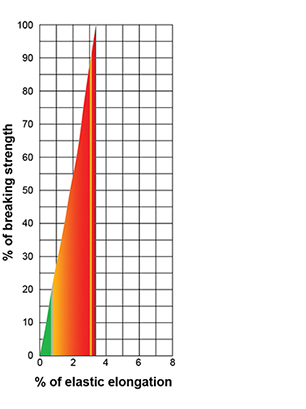

Elastic ElongationThe coloured area under the curve represents the rope’s energy absorption capability.

|