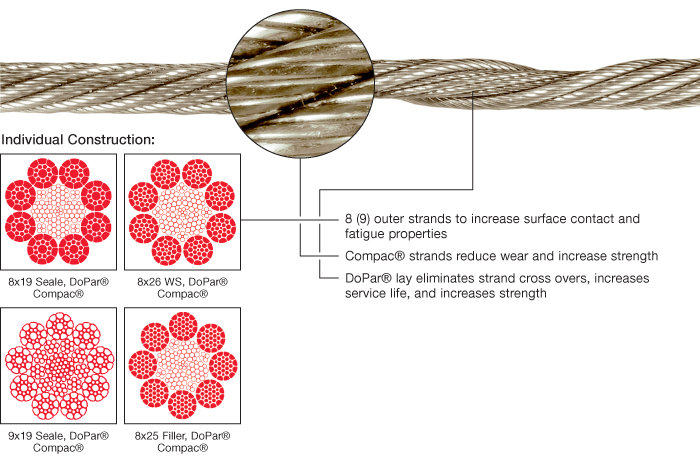

8×19 Seale, 8×25 Filler, 8×26 WS, 9×19 Seale, DoPar® and Compac®

Main Applications

High strength, high fatigue and wear resistant overhead crane wire rope.

Rope Characteristics

Combines both state of the art manufacturing technologies. The Compac® process reduces wear, increases contact area between rope and sheave, and increases strength. The DoPar® construction eliminates strand-to-strand cross overs thus reducing the risk of undetected inner rope failures. Secondly, the DoPar® lay increases the metallic fill-factor resulting in a additional strength increase.

All 8-strand constructions, and specifically all DoPar® types, require proper sheave- and drum groove dimensions. Undersized and/or worn sheaves will immediately result in rope deformations, waviness, or high strands. These ropes require extra care during installation (no reverse bend spooling).

Standard

Made to OEM Specifications.