Sheaves and Drums

|

The performance of all wire ropes is dependent on the good condition and sufficient dimensions of sheaves and drums. Too small sheaves and drums will reduce the service life of a rope. This is more a question of ‘performance’ rather than ‘safety’. The following table is based upon recommendations by the Wire Rope Technical Board. Recommended Sheave and Drum Contours: Drum Pitch for SINGLE layer minimum: 2.065 x groove radii Hardness: As wire rope has a hardness of about 50-55RC we recommend that the hardness of sheaves and drums is at least 35 RC, better is 40-45 RC. |

|

|||||||||||||||||||

|

||||||||||||||||||||

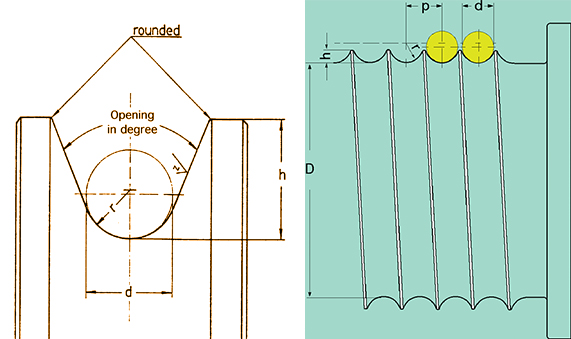

Dimensions and Inspection of SheavesA properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal rope diameter or in other words the groove diameter should be 6 to 8% larger than the nominal wire rope diameter. That means that, for example, a 23 mm nominal wire rope requires the sheave groove diameter to be between 24.38mm to 24.84 mm (radius of 12.2 mm to 12.4 mm). |

|

||||

|

When measuring sheaves it is critical that the correct gauge is used. Two types of groove gauges are widely available and knowing the difference is the difference between success and failure. No-Go Gauges with a tolerance of nominal rope diameter +2.5% is not recommended since most wire ropes made to applicable standards have an allowable tolerance of up to +5%. Therefore a sheave measured with a +2.5% No-Go gauge may result in a false confidence that the sheave is in good order. Rather it is always advised that a sheave gauge with 1% larger tolerance than the maximum allowable rope diameter is used. In the case of Python wire rope, which is made with a maximum +4% oversize tolerance, a sheave gauge with a tolerance of +5% must be used to measure the sheaves. |

|

||||

Sheave groove matches rope |

Sheave groove too small |

New rope in worn out/ too small sheave is damaged and deformed |

|||

|

For a complete discussion on Handling, Installation, Inspection, and Maintenance of Wire Rope, please ask for our separate Catalogue.

|

|||||

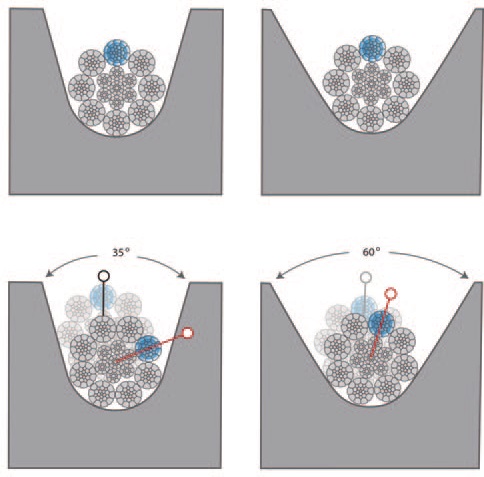

Sheave Opening AngleSheave opening angle should be 35° to 45° for applications with fleet angles up to maximum 1.5°, particularly for rotation resistant /non-rotating and DoPar rope types. For larger fleet angles use 60˚ opening. Maximum rope fleet angle for general purpose ropes should not exceed 4°. For non-rotating/rotation resistant and DoPar® types the fleet angle should not exceed 2° even with a 60° sheave opening. As you can see from below opening angles of 35˙ will introduce considerable torque into the rope as opposed to sheave opening angles of 60°. |

|

|

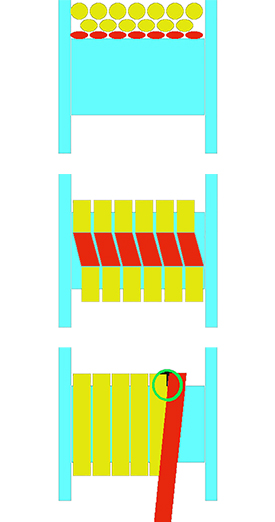

Drum WindingMulti-layer drum systems should use strand- or swage compacted Python® rope constructions having a steel core. The higher fill factor of such rope constructions will offer a greater resistance to crushing and flattening than conventional rope types. This is particularly important for boom hoist ropes on lattice boom cranes at the cross over point from one rope winding to the next. Cranes equipped with multi-layer drum systems which require rotation-resistant or non-rotating rope are best served with Python Compac® 18 and Compac® 35. To further reduce drum crushing have the rope layers wound onto the drum with about 5-10% of the WLL and avoid that the first layer unspools and re-spools without tension. This would cause a ‘soft’ bottom layer which will flatten the rope. Install ropes with 5-10% pretension of WLL to avoid “soft“ bottom layers which then “flattens” the rope rather quickly. For further information please refer to our publication “Wire Rope Inspection” |

|