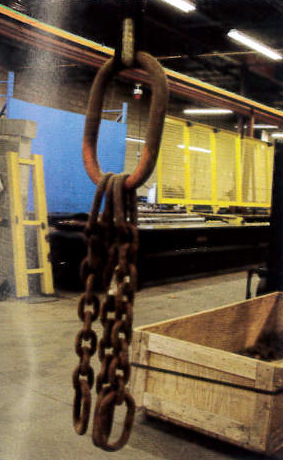

Inspection

- Daily check: visible faults in links or hooks.

- At least twice a year:

• Clean slings prior to inspection.

• Hang the chain sling up or stretch the sling out on a level floor. Remove all twists. Measure the length. Discard if sling has been stretched.

• Make a link-by-link inspection.

- At least once a year:

We recommend to have the chain sling proof tested to twice the WLL and re-certified by Unirope.

- It is important to inspect chain slings and to keep a record of individual chain inspections. The Unirope Sling Inspection Service takes care of this.

- Remove from service if you detect:

• Missing or illegible capacity tags;

• cracks or breaks, wear, nicks, gouges;

• stretched chain links or components;

• bent, twisted or deformed chain links or components;

• evidence of heat damage, weld splatter;

• pitting or corrosion;

• lack of ability to hinge freely;

• 13% or more wear on any point on a link (for exact values refer to ASME B30.9).

WE RECOMMEND TO FOLLOW ANSI B30.9 IN ITS LATEST VERSION.

Remove from service if you detect:

|

| 13% Wear |

Nicks, Cracks |

Stretch |

|

| Twisted Links, Deformed Hardware |

About the importance of sling inspections