Unitrex

Rope Characteristics

Unitrex XS Max Wear, Uniline’s high-tech cousin, is a parallel-core rope of Ultra High Molecular Weight Polyethylene (UHMWPE), wrapped with a neoprene tape and over-braided with a tough jacket of high-tenacity polyester. The result is a synthetic cable, somewhat stiffer than your usual rope, which is much like wire in its stretch characteristics.

Unlike wire, Unitrex is much lighter and easily handled. Due to its toughness, we are comfortable assigning it a higher working load rating, which is 25% of its breaking strength.

Unitrex XS Max Wear has high strength retention in service, which is supported by field studies and our long-standing track record with Uniline polyester. Unitrex’s tough rubber layer protects its UHMWPE core, and the outer jacket is saturated with urethane, making it the toughest UHMWPE rope you can buy. All of Yale’s parallel-core ropes are torque free, with bonded cores preventing contamination of the internal strength member. Unitrex XS can be quickly terminated and/or joined with a TechEye2 or TechJoin2.

Breaking Strengths

| Diameter (Inches) |

Weight (Lbs/100f) |

Average Spliced Break Strength* (Lbs) |

Minimum Spliced Break Strength* (Lbs) |

Maximum Working Load 4:1** (Lbs) |

|---|---|---|---|---|

| 0.44 | 6.7 | 20,000 | 18,000 | 5,000 |

| 0.53 | 9.2 | 26,000 | 23,400 | 6,500 |

| 0.58 | 11.4 | 34,000 | 30,600 | 8,500 |

| 0.63 | 13.5 | 42,500 | 38,250 | 10,625 |

| 0.71 | 16.9 | 50,500 | 45,450 | 12,625 |

| 0.84 | 24.2 | 73,500 | 66,150 | 18,375 |

| 1.00 | 32.4 | 100,000 | 90,000 | 25,000 |

| 1.15 | 42.4 | 125,000 | 112,500 | 31,250 |

| 1.25 | 52.5 | 158,000 | 142,200 | 39,500 |

| 1.40 | 64.9 | 195,000 | 175,500 | 48,750 |

| 1.75 | 92.6 | 264,000 | 237,600 | 66,000 |

| 1.94 | 98.8 | 310,000 | 279,000 | 77,500 |

| 1.99 | 113.3 | 360,000 | 324,000 | 90,000 |

| 2.20 | 144.0 | 430,000 | 387,000 | 107,500 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

| Diameter (mm) |

Weight (Kg/100m) |

Average Spliced Break Strength* (kg) |

Minimum Spliced Break Strength* (kg) |

Maximum Working Load 4:1** (kg) |

|---|---|---|---|---|

| 11 | 10.0 | 9,080 | 8,172 | 2,270 |

| 13 | 13.7 | 11,800 | 10,620 | 2,950 |

| 15 | 17.0 | 15,435 | 13,892 | 3,859 |

| 16 | 20.1 | 19,295 | 17,366 | 4,824 |

| 18 | 25.2 | 22,925 | 20,633 | 5,731 |

| 21 | 36.0 | 33,365 | 30,029 | 8,341 |

| 25 | 48.2 | 45,400 | 40,860 | 11,340 |

| 29 | 63.1 | 56,750 | 51,075 | 14,188 |

| 32 | 78.2 | 71,730 | 64,557 | 17,933 |

| 36 | 96.6 | 88,530 | 79,677 | 22,133 |

| 44 | 137.9 | 119,855 | 107,870 | 29,964 |

| 49 | 147.1 | 140,740 | 126,666 | 35,185 |

| 51 | 168.7 | 163,440 | 147,096 | 40,860 |

| 56 | 214.4 | 195,220 | 175,698 | 48,805 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

Rope Details

|

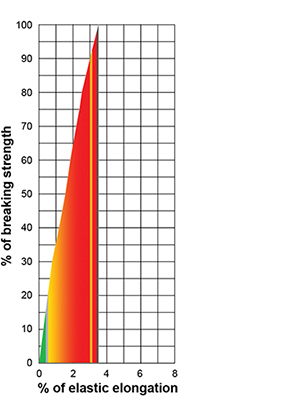

Elastic ElongationThe coloured area under the curve represents the rope’s energy absorption capability.

|