Crystalyne™

Rope Characteristics

Crystalyne is a double-braided rope constructed with an inner load-bearing core of Vectran Liquid Crystal Polymer (LCP) and has a tough polyester outer sleeve. LCP is more tolerant of bending than other high-modulus fibers and is not as affected by overloading.

Crystalyne exhibits more tension cycles to higher percentages of break than all our other high-modulus offerings. Unlike ultra-high-molecular-weight polyethylene (UHMPE) ropes, LCP fiber has little or no tendency to creep and can be used to hold tight tolerances in rope assemblies.

Vectran is hydrophobic, meaning it cannot absorb water. This rope is spliced using the same technique as our Maxibraid Plus, resulting in a termination that finishes shorter than conventional splice techniques and remains supple.

Breaking Strengths

| Diameter (Inches) |

Weight (Lbs/100f) |

Average Spliced Break Strength* (Lbs) |

Minimum Spliced Break Strength* (Lbs) |

Maximum Working Load 5:1** (Lbs) |

|---|---|---|---|---|

| 3/16 | 1.4 | 3,440 | 3,096 | 688 |

| 1/4 | 2.2 | 5,790 | 5,211 | 1,158 |

| 5/16 | 3.0 | 8,730 | 7,857 | 1,746 |

| 3/8 | 4.4 | 13,360 | 12,024 | 2,672 |

| 7/16 | 6.1 | 16,800 | 15,120 | 3,360 |

| 1/2 | 8.5 | 21,590 | 19,431 | 4,318 |

| 9/16 | 11.1 | 26,000 | 23,400 | 5,200 |

| 5/8 | 12.0 | 30,000 | 27,000 | 6,000 |

| 11/16 | 18.8 | 40,000 | 36,000 | 8,000 |

| 3/4 | 20.0 | 45,000 | 40,500 | 9,000 |

| 7/8 | 24.4 | 63,000 | 56,700 | 12,600 |

| 1 | 33.3 | 80,000 | 72,000 | 16,000 |

| 1-1/8 | 41.6 | 100,000 | 90,000 | 20,000 |

| 1-1/4 | 46.0 | 120,000 | 108,000 | 24,000 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

| Diameter (mm) |

Weight (Kg/100m) |

Average Spliced Break Strength* (kg) |

Minimum Spliced Break Strength* (kg) |

Maximum Working Load 5:1** (kg) |

|---|---|---|---|---|

| 5 | 2.1 | 1,560 | 1,404 | 312 |

| 6 | 3.3 | 2,625 | 2,363 | 525 |

| 8 | 4.5 | 3,960 | 3,564 | 792 |

| 10 | 6.6 | 6,065 | 5,459 | 1,213 |

| 11 | 9.1 | 7,625 | 6,863 | 1,525 |

| 13 | 12.7 | 9,800 | 8,820 | 1,960 |

| 14 | 16.5 | 11,800 | 10,620 | 2,360 |

| 16 | 17.9 | 13,620 | 12,258 | 2,724 |

| 17 | 28.0 | 18,160 | 16,344 | 3,632 |

| 19 | 29.8 | 20,430 | 18,387 | 4,086 |

| 22 | 36.3 | 28,600 | 25,740 | 5,720 |

| 25 | 49.6 | 36,320 | 32,688 | 7,264 |

| 29 | 61.9 | 45,400 | 40,860 | 9,080 |

| 32 | 68.5 | 54,480 | 49,032 | 10,896 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

Rope Details

Rope Benefits

|

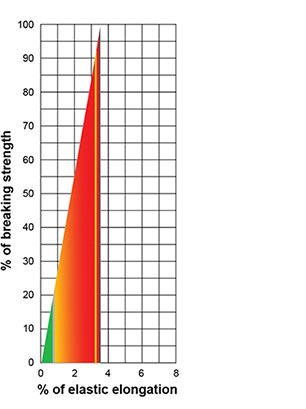

Elastic ElongationThe coloured area under the curve represents the rope’s energy absorption capability.

|