Aracom® Miniline®

Rope Characteristics

Aracom Miniline combines a low helix angle core of Technora® Aramid with a very tightly woven over-braid of thin polyester. Aracom Miniline provides the maximum strength–to-weight ratio in a composite Aramid polyester construction.

Aracom Miniline can also be ordered with fuzz fairing, which is highly effective at eliminating strum and reducing drag where application is either hydrodynamic or aerodynamic. Yale’s faired ropes can be wound on a reel without any damage to the fairing or rope. Contact Yale for more details.

Fuzz Fairings

Yale Cordage designs combinations of high- performance fairings specifically for the ocean environment in  almost any configuration. In use, they contribute significantly to drag reduction, strum suppression and longitudinal damping. Some obvious benefits are longer cable life and reduced background noise for better data. Special handling is not required, it won’t hamper deployment gear, and it is cost effective. Fairings are used on towed array configurations, drifting buoys, moored arrays (surface and subsurface), and many drogue applications due to a recently developed stiff bristle fairing.

almost any configuration. In use, they contribute significantly to drag reduction, strum suppression and longitudinal damping. Some obvious benefits are longer cable life and reduced background noise for better data. Special handling is not required, it won’t hamper deployment gear, and it is cost effective. Fairings are used on towed array configurations, drifting buoys, moored arrays (surface and subsurface), and many drogue applications due to a recently developed stiff bristle fairing.

Breaking Strengths

| Diameter (Inches) |

Weight (Lbs/100f) |

Average Spliced Break Strength* (Lbs) |

Minimum Spliced Break Strength* (Lbs) |

Maximum Working Load 5:1** (Lbs) |

|---|---|---|---|---|

| 1/16 | 0.2 | 470 | 423 | 90 |

| 3/32 | 0.4 | 890 | 801 | 170 |

| 1/8 | 0.8 | 1,730 | 1,485 | 330 |

| 5/32 | 1.0 | 2,500 | 2,160 | 480 |

| 3/16 | 1.7 | 4,200 | 3,600 | 800 |

| 1/4 | 2.5 | 6,300 | 5,400 | 1,200 |

| 5/16 | 3.3 | 8,400 | 7,200 | 1,600 |

| 3/8 | 4.2 | 13,790 | 11,520 | 2,560 |

| 7/16 | 6.7 | 17,320 | 15,210 | 3,380 |

| 1/2 | 8.0 | 22,000 | 19,800 | 4,400 |

| 9/16 | 10.6 | 30,500 | 27,450 | 6,100 |

| 5/8 | 12.0 | 36,000 | 32,400 | 7,200 |

| 3/4 | 21.0 | 56,000 | 50,400 | 11,200 |

| 7/8 | 25.9 | 78,000 | 70,200 | 15,600 |

| 1 | 33.9 | 94,000 | 84,600 | 18,800 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

| Diameter (mm) |

Weight (Kg/100m) |

Average Spliced Break Strength* (kg) |

Minimum Spliced Break Strength* (kg) |

Maximum Working Load 5:1** (kg) |

|---|---|---|---|---|

| 2 | 0.3 | 200 | 180 | 40 |

| 2 | 0.6 | 385 | 347 | 77 |

| 3 | 1.2 | 745 | 671 | 149 |

| 4 | 1.5 | 1,085 | 977 | 217 |

| 5 | 2.5 | 1,815 | 1,634 | 363 |

| 6 | 3.3 | 2,720 | 2,448 | 544 |

| 8 | 4.9 | 3,630 | 3,267 | 726 |

| 10 | 6.8 | 5,810 | 5,229 | 1,162 |

| 11 | 10 | 7,670 | 6,903 | 1,534 |

| 13 | 11.9 | 9,985 | 8,987 | 1,997 |

| 14 | 15.8 | 13,845 | 12,461 | 2,769 |

| 16 | 17.9 | 16,340 | 14,706 | 3,268 |

| 19 | 31.3 | 25,420 | 22,878 | 5,084 |

| 22 | 38.6 | 35,410 | 31,869 | 7,082 |

| 25 | 50.5 | 42,675 | 38,408 | 8,535 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

Rope Details

Rope Benefits

|

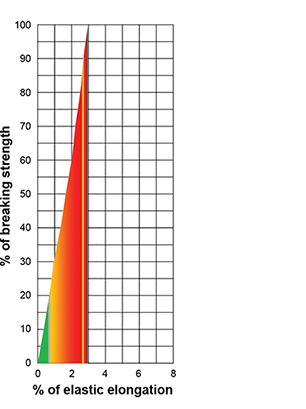

Elastic ElongationThe coloured area under the curve represents the rope’s energy absorption capability.

|