Twin-Path® Lifting Block

| These blocks are designed for high cycle lifting applications using two- or more Twin-Path® slings. The block design avoids that slings are either crunched or bunched into a single hook, or placed on top of each other into too small sister hooks. Main applications are in automotive stamping plants where the slings remain rigged to the hook/block as ‘Standard Slings’. These slings will only be taken off the hook/block for maintenance or sling inspection.

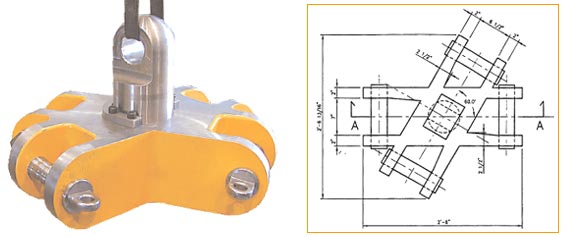

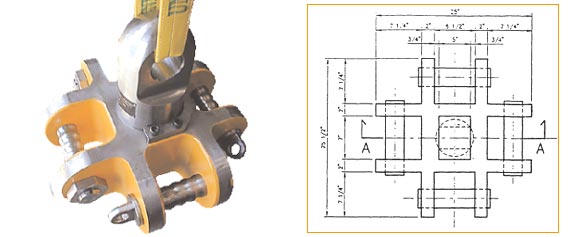

Two different styles are available: |

||||

|

||||

| Rectangular design (60° between slings) for rectangular shaped loads or dies. | ||||

|

||||

| Square design (90° between slings) for square shaped loads or dies. | ||||

|

||||

| All pins are bolt style with lock nut and cotter pins. Edges are well rounded to ensure that Twin-Path® slings do not get damaged. | WavePin™ design avoids that the sling slides to either side | |||

|

All blocks are shaped from a solid piece of 4140 Alloy steel. No welds which need inspection during service. Blocks are custom manufactured from pre-engineered designs. WLL’s generally range between 30 tons and 200 tons. Design Factor is 4:1 |

| 4-sling lift | 2-sling lift | Single point lift |