Unirope Ltd.’s Knut Buschmann won the inaugural Associated Wire Rope Fabricators (AWRF) Industry Leader Award, presented at last month’s Fall General Meeting in La Quinta, California.

The nomination for industry veteran Buschmann, who attended his first AWRF meeting in 1989, was led by the association’s incoming president, Mike Poroo, of Scope Computer Vision Technologies Corp. It was the latest of multiple awards bestowed on Buschmann, who was Unirope’s president until 2020 and served on numerous technical and standards committees.

Poroo said: “Knut has generously donated his time post-retirement to consult with me, teaching me how to think about, design, and write guidelines and standards for my business and the rigging industry. Multiple documents, several revisions, and countless hours have been involved.

“As Knut had no monetary incentive to assist,” he continued, “It became clear just how much motivation and personal fulfillment he found in being able to pass his knowledge and experience on to those that want to learn. His dedication to helping others is truly admirable and I look forward to many more years of mentorship.”

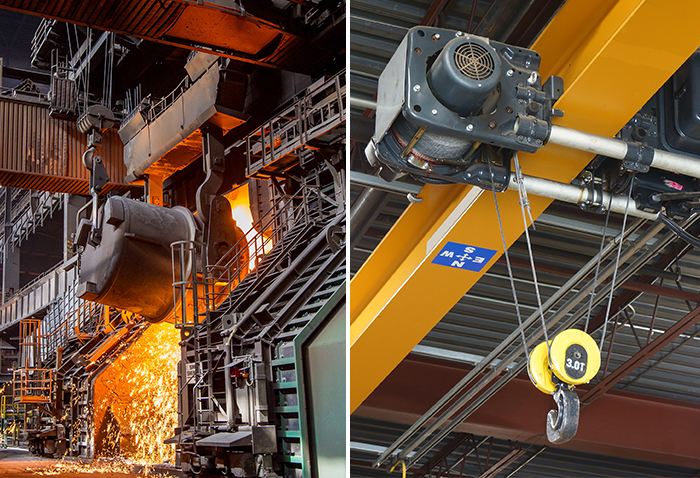

Mississauga, Ontario-based Unirope is a specialist in the manufacture, distribution, testing, certification, and inspection of high-performance wire rope and rigging products. It has additional facilities in Quebec and Alberta; the three sites combine to deliver a service nationwide and to select customers in the U.S. and Europe.

The awards program was new to this year’s AWRF Fall event, and launched to recognize major contributions towards the growth and success of the association and the rigging industry as a whole. Winners were announced during a gala evening. Categories included Industry Leader Awards in Individual and Company classifications; The Caldwell Group Inc. was the other winner.

Buschmann, who wasn’t in attendance, said: “I heard [I won] from my wife who got a text from someone else in the room during the presentation. I was much surprised because I never heard about that award before — and I thought I was up to date with AWRF board decisions.

“My initial motivation was to educate people in the subject of rope, rigging, and fabrication practices. The more people understood basic, or even advanced, engineering principals in our industry, the easier it became for me to have meaningful conversations about standards, product applications, or future directions of industry associations.”

Justin Brown, president at Unirope, and outgoing AWRF president, said: “Knut’s dedication to the lifting and rigging industry extends far beyond his impressive career; in the past year alone, he has volunteered countless hours to mentor, guide, and educate, sharing his extensive expertise to build standards that will shape our future. His contributions exemplify a commitment to quality and progress. Knut’s passion for helping others, coupled with his technical brilliance, make him a true cornerstone of our community.”

Unirope Ltd.’s Knut Buschmann attended his first AWRF meeting in 1989.

Poroo added: “There aren’t many that have contributed more to AWRF or even the rigging industry as a whole than Knut Buschmann. Without question, he is one of the brightest minds in our industry, grounded in philanthropic endeavor to raise the entire lifting and rigging community.”

Industry legacy

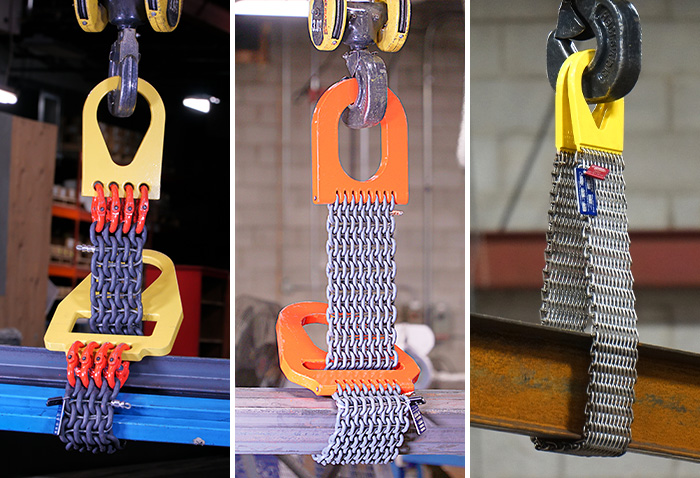

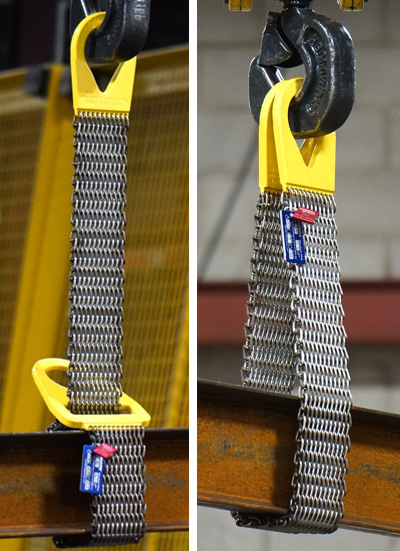

German native Buschmann moved to Canada in 1989 to lead the Unirope business. Not long after that, in 1995, he was asked to join the AWRF Technical Committee to form and chair the Web-Sling Sub-Committee. At that time, AWRF had embarked on a test program to determine the fabrication efficiencies of some wide-width and multiple ply web slings by breaking strength testing about 1,000 slings at the University of Bethlehem, Pennsylvania.

He said: “All these results landed in my lap, and, in the end, we agreed upon recommended sling capacities of such slings, which we then published and later got adopted by the WSTDA [Web Sling & Tie Down Association]. That took about two years with, how my mentor Charles Lucas always described, the ‘lightning speed of frozen molasses running down a hill’. Not long after that I joined the AWRF Board of Directors and became AWRF president for the year 2001.”

This proved to be a period of great upheaval because of illness at AWRF leadership level and the 9/11 terror attack. Having re-joined the Technical Committee, focus turned to updating the Swager Safety Guide and a pathway was opened towards the Recommended Practices and Guidelines (RP&G) that are central to the association’s function today. Buschmann led on creation of guidelines for chain and wire rope testing procedures; hoist and magnet testing; and a safety guide for test beds.

“My last assignment,” he said, “Was to develop an RP&G for Aluminum Turnback Wire Rope Terminations, which was adopted by AWRF in 2023. Along the way, I also re-designed the AWRF Quality Survey that I then morphed into the Recommended Practice for the Operation of Sling Shops, which, in turn, became the basis for the LEEA [Lifting Equipment Engineers Association] / AWRF Sling Shop Certification Program. I eventually stepped down from the AWRF Technical Committee last year.”

AWRF and LEEA are just two associations to benefit from Buschmann’s voluntary advocacy work. The International Organization for the Study of Ropes (OIPEEC) is another, where he also served as president, while other beneficiaries include the Canadian Standards Organization (CSA); Cordage Institute, which regulates fiber ropes and slings; and American Society of Mechanical Engineers (ASME). Buschmann is still active in the ASME B30.30 Rope Committee and the Infrastructure Health and Safety Association (IHSA).

He said: “In recent years, AWRF has developed more relevant technical content for members. The industry is changing quickly and is joined by young professionals not always coming with a rigging background. They are looking for guidance and inspiration on neutral ground — and AWRF can provide them with that. One has to understand that in North America, no standards exist for many of the products we are using or fabricating every day, which is different to Europe.

“The industry at large has to come together first and show that there is interest to write and design safety standards for rigging. If something falls down, gravity can do great damage — RP&Gs can guide members towards a safer and more structured way to produce and fabricate their products.”