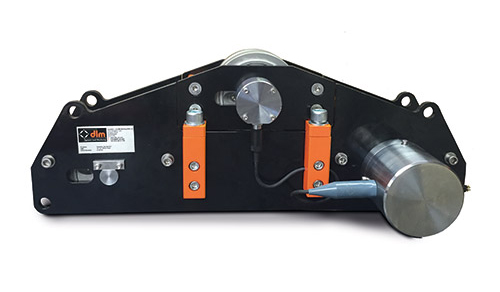

Small Running Line Monitor, RLM 60 Tonnes / 16 – 50 Rope Dia.

The DLM 60t Running Line Monitor measures the tension on a rope passing through its three wheels. Typically used in cable laying and winch operations to measure and record line tension the robust design has become an industry standard.

- Designed to be used in harsh environments, the modular design allows for easy setup, installation and servicing. Can be supplied with various diameter wheels to suit particular rope.

- The centre wheel axle is a gauged load pin load cell with a subsea rated connector for connection to the sealed integrated 4-20mA amplifier

- Line speed and distance is measured using an integrated rotary encoder mounted onto the bottom encoder wheel, in a sealed IP68 housing.

- The monitor can be supplied as a separate item for integration with customers existing PLC’s or with a DLM digital display/HMI touch screen display.

The TIMH is constructed from marine grade stainless steel and is suitable for many wire rope configurations up to 150t and will, as an option, calculate line out and speed. The TIMH has several mounting points featured in its unique design but if other mounting options are required, Straight-point can provide a custom engineered solution specific to your application.

Standard Available Wheel Sizes

Rope Diameters(mm) 16 18 19 22 24 26 28 30 32 33 38 40 44 48 50

Features:

- Fully sealed design to IP68

- Double sealed roller bearing in each sheave

- Carrying points allowing easy and safe portability

- Grease ways and greasing nipples on each axle for easy maintenance

- Robust design suitable for Offshore industry

- Integral speed and distance measurement as well as tension

- Easy to rig without the need to remove sheaves from axles

- Lifting and securing points

- Optional mounting fixtures

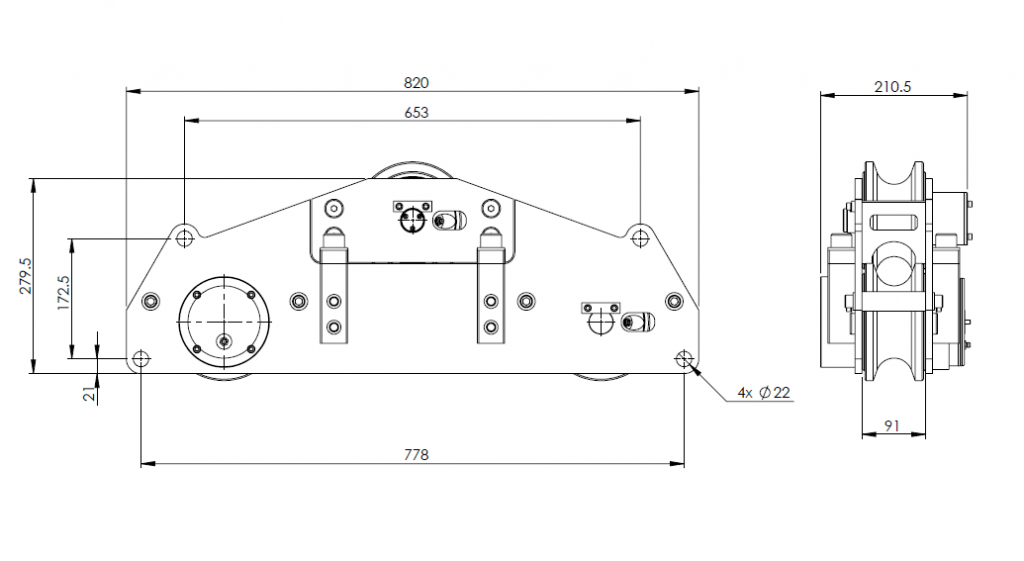

Dimensional Data

| Standard Available Wheel Sizes | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rope Diameters (mm) | 16 | 18 | 19 | 22 | 24 | 26 | 28 | 30 | 32 | 33 | 38 | 40 | 44 | 48 | 52 | 60 | 64 |

Note: others available upon request

| Specifications | |

|---|---|

| Part Number | 0001 – 1115 |

| Frame Construction | CNC machined side plates. Side plates fixed together using high tensile Stainless Steel Bolts and supporting spacers. No welded joints. Dual frame construction (Upper and Lower) for easy rigging and rope insertion. IP68 O Ring sealed Encoder protection casing, located to the side of the encoder on lower frame. Upper and Lower Frames attached together using high tensile Stainless Steel bolts. Marine Grade DP4B Bearings used on all wheels. |

| Frame Finish | Colour to suit customer requirements (Orange and Black as standard) Epoxy Powder Coat (170u thickness as standard). Optional Zinc plating prior to Powder coat for extra protection. |

| Wheel Material | EN24T alloy Steel (Hardened to 40 Rockwell upon request) |

| Axles and Shear Pin Material | 17-4PH H1150 + 1150 Stainless Steel. |

| Shear Pin Load Cell Axle | Suitable for Line Tensions up to 80t. Connection through MCBH-3-FS and MCIL-3-MP Subsea connectors and IP68 gland to sealed Encoder casing. O Ring Sealed. |

| Amplifier | 3 Wire 4-20mA current source. 11-24VDC Powered. Mounted in Shear Pin Load Cell head, signal and power connection through MCBH-8-MP Bulkhead Connector shared with Encoder output/input, mounted on Encoder protective casing. |

| Encoder | Mounted inside O Ring sealed Encoder casing bolted to frame. Push-Pull Quadrature output. 11-24VDC Powered. Signal and Power Connection through MCBH-8-MP Bulkhead connector shared with Amplifier output/input. Located in bottom Encoder casing mounted to wheel axle by encoder coupling. |

| RLM Mounting | Eight machined eyes located on each side plate for easy rigging to spooling gear or for use as lifting points. Machined stainless steel spacers double as lifting/carrying points. |

| Optional Extras | Fleeting Gear Mounting posts Mounting brackets |