Inspection of Wire Mesh Slings

Unirope® Wire Mesh Sling Inspection Criteria (based on ASME B30.9-3)

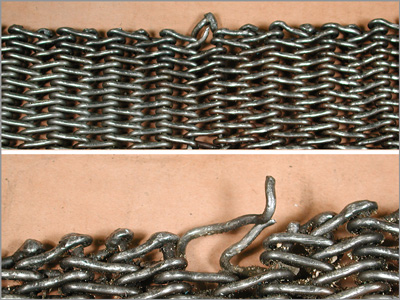

Broken wires in any part of the mesh. |

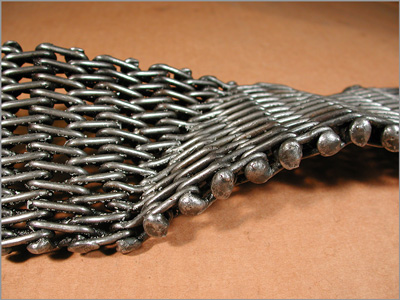

Worn/abraided spirals and spiral-to-fitting interaction. |

Distortion of the fittings. |

Lack of flexibility and distortion of the mesh. |

A metal mesh sling shall be removed from service if any of the following conditions are present:

- missing or illegible sling identification.

- broken weld or a broken brazed joint along the sling edge.

- broken wire in any part of the mesh.

- reduction in wire diameter of 25% due to abrasion or 15% due to corrosion.

- lack of flexibility due to distortion of the mesh.

- distortion of the choker fitting so the depth of the slot is increased by more than 10%.

- distortion of either end fitting so the width of the eye opening is decreased by more than 10%.

- a 15% reduction of the original cross-sectional area of any point around the hook opening of the end fitting.

- visible distortion of either end fitting out of its plane.

- cracked end fitting.

- slings in which the spirals are locked or without free articulation shall not be used.

- fittings that are pitted, corroded, cracked, bent, twisted, gouged, or broken.

- other conditions, including visible damage, that cause doubt as to the continued use of the sling.

For sling inspection, re-certification and proof testing call Unirope®