Button spelter sockets come in seemingly endless dimensions and configurations. Nearly every crane manufacturer is using a different type and sized button making the logistics impossible to keep every type of button for every type of manufacturer for every rope size available at any time.

Also, many crane users have adopted other ‘after market’ systems which use different hardware than the crane OEM.

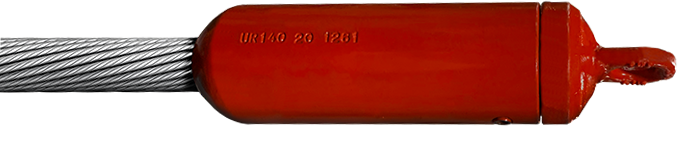

We at Unirope designed a universal type of round Torpedo Button which can be configured to fit most “baskets” or “pouches” in the field.

These Torpedo Buttons are made 100% in our own in-house machine shop using highest quality tool steels which are heat treated and hardened to over 45RC to ensure durability and strength.

Unirope Torpedo Buttons comply to EN 13411-4 and, in addition, have been Fatigue Type Tested to 75,000 cycles.

We design these buttons, we make these buttons, we install these buttons, we proof test these buttons.