Wire Rope Selection

Overhead Cranes

Due to the vast variety of overhead cranes in service there is no ‘standard’ rope construction which would fit all types. In most cases, cranes made in North America require imperial size ropes either, Class 6×19 or 6×36 are the traditional choices.

To enhance the crane performance the use of Python® High Performance rope is recommended. Python® wire rope can replace traditional 6-strand constructions without any changes to the crane, other than making sure the sheaves and drum are in good condition.

If you upgrade from a standard strength 6-strand or 6-strand die-drawn type select Python® Super 8C, in either left- or right hand lay. This type exceeds the breaking strength requirement and will greatly outperform any traditional rope due to the strand compaction process. When using left- and right hand lay rope in tandem we recommend corresponding drum grooving to ensures the most stable rope block you can imagine. A further increase in breaking strength (between 1% and 7% depending on tensile class) can be achieved by selecting Python® Super 8V which is a swage compacted type. For smaller cranes we suggest Python® Compac 8 which we carry in the popular sizes between 6.5 mm and 11 mm. This is a VERY hight strength type.

If you experienced some block twisting and can not use left- and right hand lay rope in tandem you want to select Python® MULTI. Even slight block twisting is a constant inconvenience when you have to position a C-clamp into stacked coils, for example.

Another application is where both rope ends are attached to the drum. The result is that 1/2 of the rope always spools into a incorrect drum grooving direction. Particularly 8-strand ropes without a plastic coated core (as provided by most OEM’s) tend to torque resulting in loose strands and waviness. Using Python® MULTI reduces and, in most cases, eliminates such problems. Because of it’s very unique construction Python-MULTI does NOT require corresponding drum grooving and still has shown the highest degree of service life increase of all Python types.

Some North American made overhead cranes have been converted, or can be converted, to higher lifting capacities using high strength Python® SUPER 8 (all types), Python® Power 9V or Python® Ultra compacted constructions. We suggest not to attempt to convert your crane without professional advice, nor to select such without consultation with your local Python Distributor.

Overhead Cranes and Rotation Resistant Ropes

As a rule, Non-Rotating or Rotation Resistant rope types shall only be used if the lower sheave block tends to spin and Python® Multi did not cure the problem. Generally, non-rotating ropes will have a LOWER fatigue life than standard constructions, although they seem to have ‘finer’ wires and appear to be more flexible. Specifically 9×17 spin resistant, 19×7, 19×19, and 24×7 rotation resistant ropes tend to break up from the inside and require frequent and careful inspections. Most of these rope types on overhead cranes are smaller sizes between 5/16″ and 7/16″ (between 5 mm and 11 mm).

For rope diameter larger than 5/15” (8 mm) we recommend Python®-Compac 35 or Type 35P with a plastic coated core to prevent premature internal wire breaks.

Under no circumstances do we recommend Python® Compac 18 for such applications.

Scrap and Grab Cranes, Pile Drivers

These are, in essence, “wire rope destruction machines”. Some users had good results with 6×19 COMPAC® ropes, others prefer the simplicity of standard 6×19 ropes. For shock loading applications, some users have had very good results with Python® Super 8C or V yet, there were reports also of good performance with plastic impregnated filled rope types (BXL, PFV or Cushion ropes are some trade names). In essence, we believe that the human factor, crane design, crane location, and scope of work creates such a mix of conflicting requirements that we, as the rope supplier, can only suggest that whatever works best for YOU in YOUR specific situation is also the best rope for you. This may not be the case for the chap next door.

Hoisting Rope for Mobile Cranes

Most of the smaller capacity US made cranes like Grove, Terex, P&H, Century, National, operate best with Python® Compac 18. This strand compacted rope is superior on multiple layer drums where traditional ropes tend to fail due to friction damages at the winding crossover points. However, Python® Compac 18, when used to its full fatigue life, tends to break up from the inside out (as all 19×7/19×19 rope does). Therefore, in high cycle applications we recommend Python® Compac 35 as this rope combines high strength, low rotation and die-drawn strands at a very attractive price. For some high load ratings (e.g. on Manitowoc’s) Python® Compac 35PLUS ropes are either already installed by the crane manufacturer or are our recommended rope choice. Under NO circumstances do we recommend the so called 8×19 spin resistant’ rope constructions. In service these types of ropes WILL break-up from the inside out and when used with one end free to rotate they lose up to 40% of their breaking strengths. Catastrophic and unexpected rope failures are the result.

Hoist Rope on Tower Cranes

Note that CSA Z248 does NOT allow 8×19, 19×7, 19×19 or similar rotation resistant ropes to be used. See 4.11.1 d)ii) which states that “Rotation-resistant wire rope shall not be used …. unless the rope has 15 outer strands or more (ASTM A1023/A1023M Category 1 wire rope) or the inner core is plastic coated.” For tower cranes this includes our Python® Compac 18.

Rotation Resistant ropes (having less than 14 outer strands) are very difficult to inspect since they tend to fatigue from the inside-out of the rope. Also, nearly all European tower cranes require high strength non-rotating ropes and neither 19×7 nor 19×19 types fulfill the demand on strength and/or on non-rotating properties.

For the older Pecco “double sheave lower suitcase block”, which is used strictly in a 2-line configuration, a regular 6×36 IWRC rope is sufficient, provided the building height is no more than 10-12 floors. Here, large line spacing prevents the block from spinning.

For all other cranes we recommend Python® Compac 35.

Linden, some Kroll- and Comedil tower cranes which have the 3- or 4 sheave arrangement in the block are ‘rope killers’. The reverse bend in such systems is so severe that short rope life MUST be expected. Under NO circumstances should you use 19×7/19×19 ropes. Even if you use our Python® non-rotating ropes we will NOT guarantee against bird-cages and other rope deformations as a result of such reeving systems. There have been reported sudden and unexpected rope failures. Such set ups are quick and easy to convert from a 2 part to a 4-part line but it’s not ideal from a wire rope standpoint … and there is nothing we can do about it; you simply have to learn to live with it and INSPECT … INSPECT … INSPECT !

|

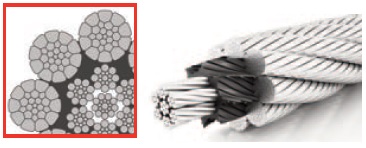

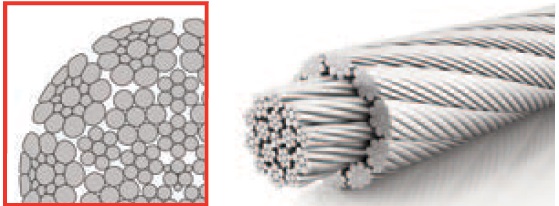

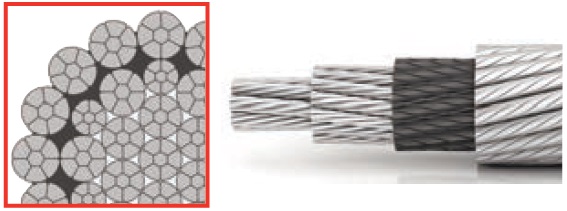

Python® Super 8 (Types: Regular, strand compacted, swaged compacted, and DoPar)8-strand overhead crane wire rope with a plastic coated core to increase operating life, and to provide for permanent core lubrication. Type Super 8 C is a strand compacted rope for increased fatigue life, Super 8V is swaged compacted for increased strength and Super 8 CD is a DoPar HiPac type for highest strength in this rope class. |

|

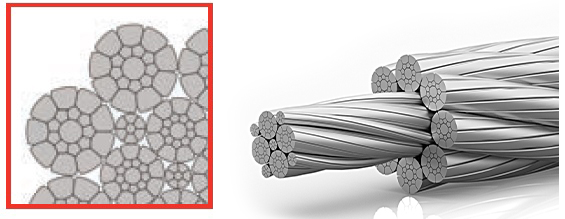

Python® Compac 88-strand HiPac® and DoPar® constructed rope for fast running overhead cranes. Extreme high breaking strength with super flexibility and long duty cycle ratings. Is available in small imperial and metric sizes 1/4” to 18 mm. |

|

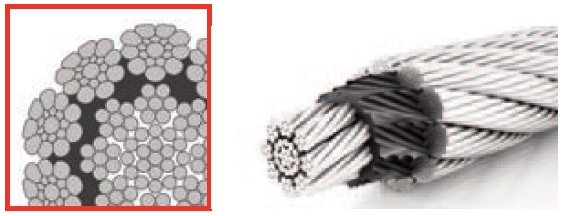

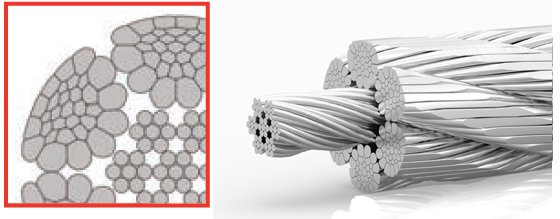

Python® Multi10 Outer strands, Category 3 rotation resistant. Developed for maximum performance on overhead cranes. This 10-strand rope features a plastic coated core for extended fatigue life performance and permanent core lubrication. Python® Multi is spin resistant to reduce block twisting on overhead cranes. |

|

Python® Power 99-strand all steel high strength type for overhead cranes. ForcePac® swaged compacted to enhance abrasion characteristic and to reduce sheave- and drum wear. DoPar® Long Life construction provides up to 40% strength increase over standard 6-strand constructions and increased duty cycles due to enhance inner parallel strands. |

|

Python® Ultra10-strand ultra high strength DoPar® and ForcePac® type mainly used as high fatigue resistant rope for engineered cable assemblies. Up to 55% strength increase over standard 6-strand constructions. Sensitive to introduced rotation so call before you select this rope for overhead crane applications. |

|

Python® Construct-6High strength ForcePac® 6-strand rope for applications which require a crush resistant rope to be used on multiple layer winding systems. Because constructional stretch is near zero it can be used where a ‘pre-stretched’ rope would be required. |

|

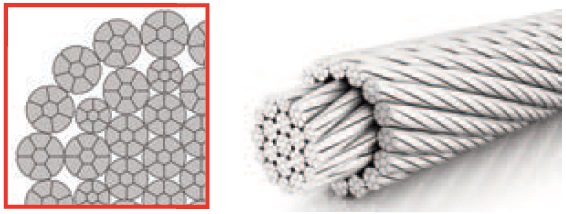

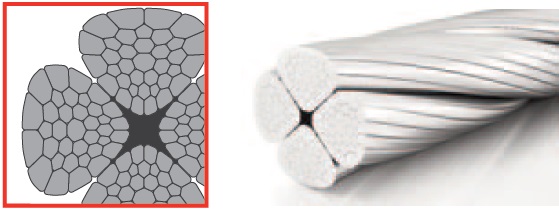

Python® Compac 1812 outer strands, Category 2. Due to the larger number of individual wires it is more flexible than 19×7. The rope is made with our HiPac® strands to provide for better drum spooling and less core abrasion. Recommended for Grove, Terex-, Century- Link-Belt-, and National cranes. NOT to be used with a swivel. |

|

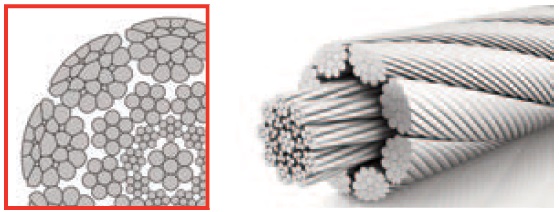

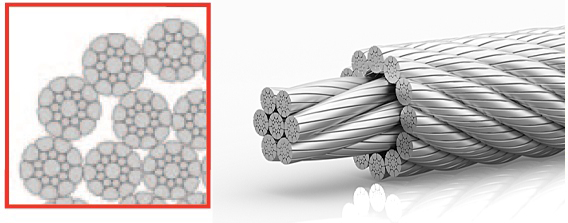

Python® Compac 35 and Compac 35 Plus16 outer and 19 inner HiPac® strands, Category 1 rotation resistance. Recommended to be used on tower- and European type mobile cranes. Available in left- and right hand lay as well as in regular- and lang’s lay constructions. Made to also be used in single line applications. ALLOWED to be used with a swivel. Compac 35 is available from 5/16” to 4” diameter! |

|

Python® Compac 35PSame as Compac 35 above (Category 1 rotation resistance) but with a plastic coated core to increase fatigue life and to prevent premature inner wire breaks. Encapsulated core provides core lubrication retention. Strand compaction increases strength and sheave contact area. ALLOWED to be used with a swivel. Available from 5/16” to 4” diameter! |

|

Python® 4-RUNNERPython® 4-RUNNER was developed for ship cranes using bulk grabs to unload coal, iron ore, and other abrasive bulk loads. Because of it’s crush resistance it is also used on pile drivers and other heavy duty construction equipment which requires a crush resistant rope for multiple layer windings, even on smooth drums. |