Wire Rope Tag System

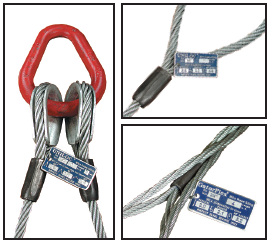

Unirope went through the expense to develop a wire rope sling tagging system which lasts. The tag itself is made from super sturdy 1/8″ thick aluminum plate. All information is deep etched and/or deep impression stamped into the tag. For many rope sizes the capacity information is already etched in with large legible numbers so users can actually read the tag from about 6 ft away. That in itself is a huge step forward in plant and construction site safety.

The following sling types are tagged FREE OF CHARGE with the ALUMINUM tag system:

- Wire Rope Bridle Slings (2-, 3-, 4- leg slings)

regardless of rope construction and type - Gator Flex-, Gator-Laid-, and Tri-Flex- Slings

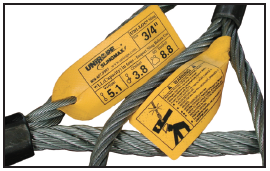

In addition we have developed a vinyl tag system. For the most popular sling sizes we have pre-printed tags with large legible capacity information and important safety precautions on the back side of the tag. The tag is spliced into the sling and can not ‘ride’ onto the sling body; it will remain in the protected ‘crotch’ area of the sling loop.

The following sling types are tagged FREE OF CHARGE with the VINYL tag system:

- Standard single leg wire rope slings

- Cable laid Slings

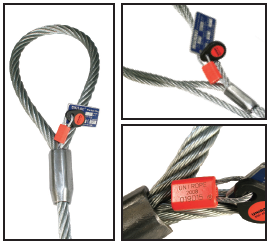

As an option, We can attach an RFID (radio frequency identification) tag.

This system allows us and our customers to:

- Perform inspections and print inspection certificates on demand

- Allows our customers to view and print their inspection certificates through their web browser

- Have instantly available documents such as safety- inspection, and product information

- Record rigging product repair and re-certifications made by Unirope

- Have a record of your entire sling inventory sorted by type, location within your plant, past- and next required safety inspection

- Move- and record sling locations around your plant

- Share inspection- and test certificate records with government auditing bodies

- Make better decisions about your sling’s performance by analyzing maintenance data

- Can be retrofitted to any existing sling product