Aracom® 100

Rope Characteristics

Aracom 100 is a 12-strand rope comprised of 100% Technora® Aramid fiber. Teijin’s Technora® Aramid is selected for this rope due to its ease of handling and reduced internal yarn-on-yarn friction, which greatly increases this Aramid’s longevity.

Before we twist this fiber we over apply our own exclusive Aralube coating which improves its translation efficiency as we process it through our manufacturing facility. The rope is twisted and braided with sufficient firmness to be considered self-supporting although many users opt for our Maxijacket urethane coated version which greatly increases its abrasion resistance. Aramid has inherent temperature resistance and has little creep once the rope’s permanent elongation is exercised out.

Breaking Strengths

| Diameter (Inches) |

Weight (Lbs/100f) |

Average Spliced Break Strength* (Lbs) |

Minimum Spliced Break Strength* (Lbs) |

Maximum Working Load 5:1** (Lbs) |

|---|---|---|---|---|

| 1/8 | 0.5 | 2,200 | 1,980 | 440 |

| 5/32 | 0.9 | 3,640 | 3,276 | 728 |

| 3/16 | 1.1 | 5,590 | 5,031 | 1,118 |

| 1/4 | 2.0 | 9,150 | 8,235 | 1,830 |

| 5/16 | 3.1 | 13,600 | 12,240 | 2,720 |

| 3/8 | 4.4 | 17,600 | 15,840 | 3,520 |

| 7/16 | 5.6 | 23,650 | 21,285 | 4,730 |

| 1/2 | 6.8 | 28,600 | 25,740 | 5,720 |

| 9/16 | 10.3 | 37,590 | 33,831 | 7,518 |

| 5/8 | 12.5 | 51,000 | 45,900 | 10,200 |

| 3/4 | 18.5 | 66,300 | 59,670 | 13,260 |

| 7/8 | 24.1 | 85,680 | 77,112 | 17,136 |

| 1 | 29.6 | 102,000 | 91,800 | 20,400 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

| Diameter (mm) |

Weight (Kg/100m) |

Average Spliced Break Strength* (kg) |

Minimum Spliced Break Strength* (kg) |

Maximum Working Load 5:1** (kg) |

|---|---|---|---|---|

| 3 | 0.7 | 995 | 896 | 199 |

| 4 | 1.3 | 1,650 | 1,485 | 330 |

| 5 | 1.6 | 2,535 | 2,282 | 507 |

| 6 | 3.0 | 4,150 | 3,735 | 830 |

| 8 | 4.6 | 6,170 | 5,553 | 1,234 |

| 10 | 6.6 | 7,990 | 7,191 | 1,598 |

| 11 | 8.3 | 10,735 | 9,662 | 2,147 |

| 13 | 10.1 | 12,980 | 11,682 | 2,596 |

| 14 | 15.3 | 17,065 | 15,359 | 3,413 |

| 16 | 18.6 | 23,150 | 20,835 | 4,630 |

| 19 | 27.5 | 30,100 | 27,090 | 6,020 |

| 22 | 35.9 | 38,895 | 35,006 | 7,779 |

| 25 | 44.1 | 46,305 | 41,675 | 9,261 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

Rope Details

Rope Benefits

|

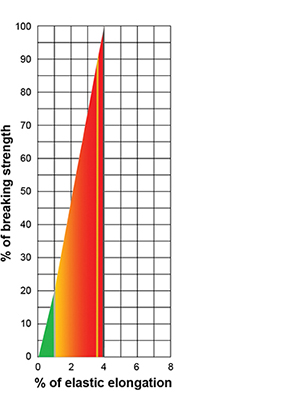

Elastic ElongationThe coloured area under the curve represents the rope’s energy absorption capability.

|

||||||||||||||