Aracom T®

Rope Characteristics

Aracom T is a double braid consisting of a Technora® Aramid core with a sleeve of high-tenacity polyester. Aracom T maintains a high degree of flexibility and is easily spliced.

Yale’s exclusive Aralube process infuses the Technora® with molten lubricant prior to entering our twisting equipment. Lab and field experience have shown that this added, internal permanent lubrication (nonsoluble) treatment leads to an extended wear life (as much as four times). It cuts down internal abrasion, reduces lament breakage in processing and helps us manage fiber tensions in the factory as we ply up a strand. The polyester sleeve is thicker than its sister product, Miniline, which gives it better protection in high-abrasion applications. The entire strength of Aracom T is derived from the core, and the sleeve’s purpose is to protect the core from abrasion.

Breaking Strengths

| Diameter (Inches) |

Weight (Lbs/100f) |

Average Spliced Break Strength* (Lbs) |

Minimum Spliced Break Strength* (Lbs) |

Maximum Working Load 5:1** (Lbs) |

|---|---|---|---|---|

| 3/16 | 1.5 | 4,800 | 4,320 | 960 |

| 1/4 | 2.7 | 6,800 | 6,120 | 1,360 |

| 5/16 | 3.8 | 9,700 | 8,730 | 1,940 |

| 3/8 | 5.1 | 14,500 | 13,050 | 2,900 |

| 7/16 | 6.8 | 17,500 | 15,750 | 3,500 |

| 1/2 | 8.7 | 23,000 | 20,700 | 4,600 |

| 9/16 | 10.0 | 27,500 | 24,750 | 5,500 |

| 5/8 | 13.3 | 34,350 | 30,915 | 6,870 |

| 3/4 | 16.9 | 39,390 | 35,451 | 7,878 |

| 7/8 | 24.5 | 69,400 | 62,460 | 13,880 |

| 1 | 32.5 | 86,800 | 78,120 | 17,360 |

| 1-1/8 | 45.0 | 97,850 | 88,065 | 19,570 |

| 1-1/4 | 51.0 | 110,000 | 99,000 | 22,000 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

| Diameter (mm) |

Weight (Kg/100m) |

Average Spliced Break Strength* (kg) |

Minimum Spliced Break Strength* (kg) |

Maximum Working Load 5:1** (kg) |

|---|---|---|---|---|

| 5 | 2.2 | 2,175 | 1,958 | 435 |

| 6 | 4.0 | 3,085 | 2,777 | 617 |

| 8 | 5.7 | 4,400 | 3,960 | 880 |

| 10 | 7.6 | 6,580 | 5,922 | 1,271 |

| 11 | 10.1 | 7,945 | 7,151 | 1,589 |

| 13 | 13.0 | 10,440 | 9,396 | 2,133 |

| 14 | 14.9 | 12,485 | 11,237 | 2,497 |

| 16 | 19.8 | 15,590 | 14,031 | 3,087 |

| 19 | 25.2 | 17,880 | 16,092 | 3,541 |

| 22 | 36.5 | 31,505 | 28,355 | 5,538 |

| 25 | 48.4 | 39,405 | 35,465 | 7,264 |

| 29 | 67.0 | 44,420 | 39,978 | 8,626 |

| 32 | 75.9 | 49,940 | 44,946 | 9,806 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

Rope Details

Rope Benefits

|

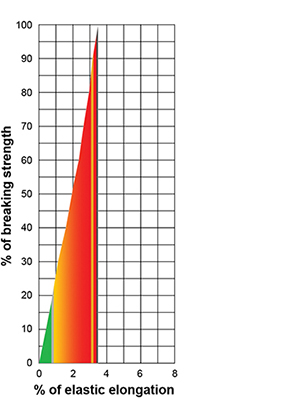

Elastic ElongationThe coloured area under the curve represents the rope’s energy absorption capability.

|