DoPar® LONGLIFE® Rope Design

![]()

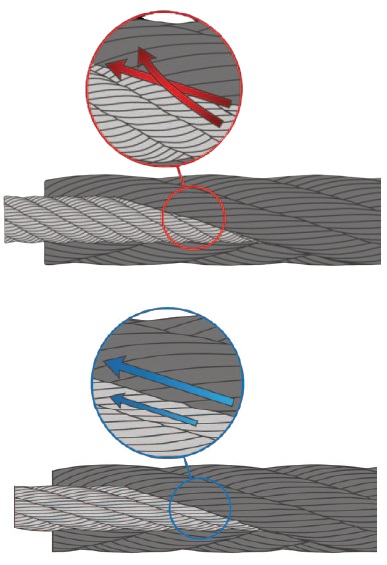

In conventionally designed wire rope, strands of different layers are arranged in a way that they cross at angles. Such a design causes nicking in the wires of adjacent strand layers. Nicked wires will break prematurely, and if not detected, can lead to core failure during service.

Certain PYTHON rope constructions feature our DoPar® rope design that avoids internal wire and strand crossings. As a result, the wire rope provides superior fatigue resistance and therefore extended lifetime.

An added benefit for DoPar® enabled PYTHON rope is their extremely high breaking strength. DoPar® increases the metallic cross section area (fill factor) which results in breakloads significantly higher than in other constructions.

DoPar® rope design avoids internal wire and strand cross over.

Skill and Expertise

PYTHON® wire ropes wouldn’t be special without the skills of our workers. While technology is an important factor, a major part of making wire rope is still craftsmanship. Skilled workers with high expertise are required to make ropes which meet our high design criteria.

WDI is proud of our personnel that embrace their jobs with an exceptional will to excel. Their dedication is proven by a very low employee turnover, resulting in an average job tenure of 20 years. We realize this as being one of our biggest assets. In order to keep this knowledge within the company, it is our philosophy to constantly develop and transfer skills to the younger generation.