Double Esterlon™

Rope Characteristics

Double Esterlon is a double-braided rope constructed of premium over finish polyester fiber in both the sleeve and core. This product is identified by two green strands braided into the cover structure and is available with optional Maxijacket urethane coating to further enhance the rope’s wear resistance.

Double Esterlon has low stretch, high dielectric strength, and excellent wear life. Double Esterlon yields the highest-strength double braid polyester available. It is completely spliceable, delivering the cataloged strengths when spliced properly.

Breaking Strengths

| Diameter (Inches) |

Weight (Lbs/100f) |

Average Spliced Break Strength* (Lbs) |

Minimum Spliced Break Strength* (Lbs) |

Maximum Working Load 5:1** (Lbs) |

|---|---|---|---|---|

| 1/4 | 2.4 | 2,940 | 2,646 | 588 |

| 5/16 | 3.2 | 3,750 | 3,375 | 750 |

| 3/8 | 4.2 | 5,740 | 5,166 | 1,148 |

| 7/16 | 5.7 | 7,690 | 6,921 | 1,538 |

| 1/2 | 7.8 | 11,000 | 9,900 | 2,200 |

| 9/16 | 9.8 | 13,290 | 11,961 | 2,658 |

| 5/8 | 13.9 | 17,540 | 15,786 | 3,508 |

| 3/4 | 16.5 | 20,800 | 18,720 | 4,160 |

| 7/8 | 23.8 | 33,000 | 29,700 | 6,600 |

| 1 | 33.7 | 46,200 | 41,580 | 9,240 |

| 1-1/16 | 39.1 | 47,500 | 42,750 | 9,500 |

| 1-1/8 | 44.7 | 54,100 | 48,690 | 10,820 |

| 1-1/4 | 50.9 | 63,700 | 57,330 | 12,740 |

| 1-5/16 | 57.4 | 70,360 | 63,324 | 14,072 |

| 1-1/2 | 70.1 | 88,890 | 80,001 | 17,778 |

| 1-5/8 | 83.2 | 93,710 | 84,339 | 18,742 |

| 1-3/4 | 103.0 | 111,930 | 100,737 | 22,386 |

| 2 | 123.5 | 133,450 | 120,105 | 26,690 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

| Diameter (mm) |

Weight (Kg/100m) |

Average Spliced Break Strength* (kg) |

Minimum Spliced Break Strength* (kg) |

Maximum Working Load 5:1** (kg) |

|---|---|---|---|---|

| 6 | 3.6 | 1,330 | 1,197 | 266 |

| 8 | 4.8 | 1,700 | 1,530 | 340 |

| 10 | 6.3 | 2,605 | 2,345 | 521 |

| 11 | 8.5 | 3,490 | 3,141 | 698 |

| 13 | 11.6 | 4,990 | 4,491 | 998 |

| 14 | 14.6 | 6,030 | 5,427 | 1,206 |

| 16 | 20.8 | 7,960 | 7,164 | 1,592 |

| 19 | 24.6 | 9,440 | 8,496 | 1,888 |

| 22 | 35.4 | 14,980 | 13,482 | 2,996 |

| 25 | 50.2 | 20,970 | 18,873 | 4,194 |

| 27 | 58.2 | 21,565 | 19,409 | 4,313 |

| 29 | 66.5 | 24,560 | 22,104 | 4,912 |

| 32 | 75.8 | 28,915 | 26,024 | 5,783 |

| 33 | 85.5 | 31,940 | 28,746 | 6,388 |

| 38 | 104.4 | 40,355 | 36,320 | 8,071 |

| 41 | 123.9 | 42,540 | 38,286 | 8,508 |

| 44 | 153.3 | 50,815 | 45,734 | 10,163 |

| 51 | 183.9 | 60,585 | 54,527 | 12,117 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

Rope Details

Rope Benefits

|

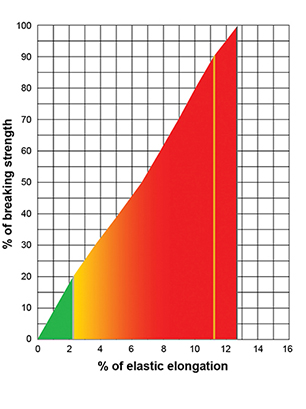

Elastic ElongationThe coloured area under the curve represents the rope’s energy absorption capability.

|