Hy-Dee Brait

Rope Characteristics

Hy-Dee Brait is an 8-strand bi-polymer rope with extraordinary dielectric properties. The rope is nubby, which provides excellent grip, and treated with a proprietary chemical mixture Yale calls Aralube-dielectric.

This treatment is the key to Hy-Dee Brait’s wet dielectric performance and allows us to make the highest dielectric-strength rope commercially available. It is easy to splice with a tucking procedure or by the quick splice method.

This product is 100% lot tested for dielectric conformance.

Breaking Strengths

| Diameter (Inches) |

Weight (Lbs/100f) |

Average Spliced Break Strength* (Lbs) |

Minimum Spliced Break Strength* (Lbs) |

Maximum Working Load 8:1** (Lbs) |

|---|---|---|---|---|

| 1/4 | 1.6 | 1,600 | 1,440 | 200 |

| 3/8 | 3.3 | 3,200 | 2,880 | 400 |

| 1/2 | 5.6 | 5,600 | 5,040 | 700 |

| 9/16 | 6.4 | 6,300 | 5,670 | 788 |

| 5/8 | 8.0 | 7,800 | 7,020 | 975 |

| 3/4 | 11.2 | 10,500 | 9,450 | 1,313 |

| 1 1/8 | 21.0 | 18,000 | 16,200 | 2,250 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

| Diameter (mm) |

Weight (Kg/100m) |

Average Spliced Break Strength* (kg) |

Minimum Spliced Break Strength* (kg) |

Maximum Working Load 8:1** (kg) |

|---|---|---|---|---|

| 6 | 2.4 | 725 | 653 | 90 |

| 10 | 4.9 | 1,450 | 1,305 | 180 |

| 13 | 8.3 | 2,540 | 2,286 | 315 |

| 14 | 9.5 | 2,860 | 2,574 | 355 |

| 16 | 11.9 | 3,540 | 3,186 | 440 |

| 19 | 16.7 | 4,765 | 4,289 | 595 |

| 29 | 31.3 | 8,170 | 7,353 | 1,020 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

Rope Details

Rope Benefits

|

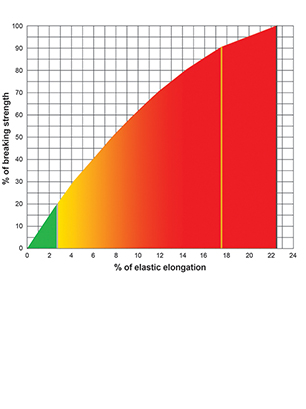

Elastic ElongationThe coloured area under the curve represents the rope’s energy absorption capability.

|