Python® Super 8C

High Performance, High Strength, coated core (HiPac®, PlastGuard®)

- 8-strand fatigue resistant construction for best performance

- HiPac® design to increase fatigue life and strength

- Shaped outer wires for optimum sheave contact

- PlastGuard® coated core helps prevent inner wire breaks

- Permanent lubricated core

Main Applications

Super-8C is the classic ‘upgrade’ rope for all overhead crane types for increased rope service life performance while maintaining the ability to operate with fleet angles up to 4˚. The 8-strand construction provides an excellent combination of fatigue life and abrasion resistance also in multi layer spooling applications.

This rope is the ideal choice for container- and port cranes as well as a boom hoist rope with luffing jib tower cranes which spool the rope onto multiple layer drums.

Rope Characteristics

8-strand high performance overhead crane wire rope with a plastic coated core. This special engineered hard plastic prevents metal to metal contact between outer- and inner strands and greatly reduces internal, non-detectable, wear and abrasion resulting in increased fatigue life, plus it provides for permanent core lubrication.

This rope is strand compacted for increased surface contact area between rope and sheave thus reducing sheave and drum wear.

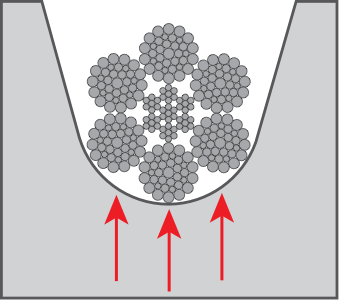

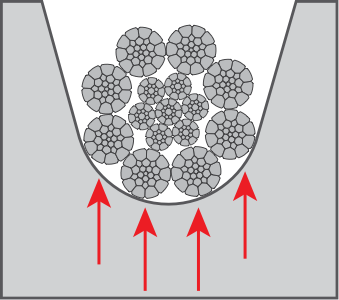

| 6-strand | 8-strand | |

|---|---|---|

|

|

The 8-strand construction provides an increase in contact points between rope and sheave. Less wear of the rope and of your equipment.

Standard

EN 10264, 12385 where applicable

Available in right regular lay (RRL) AND left regular lay (LRL).

Available in right regular lay (RRL) AND left regular lay (LRL).

Breaking Strengths

Note: The maximum CAPACITY, WORKING LOAD LIMIT (WLL), or LINE PULL of the rope usually is 1/5 of the below stated values. For specific information consult the standards applicable to your rope application.

| Python® Super 8C | ||||

|---|---|---|---|---|

| Minimum Strength tons of 2,000 lbs | ||||

| Rope dia. inch | IPS | EIPS | EEIPS | Weight per foot lbs |

| 1/4 | 3.4 | 3.7 | 4.0 | 0.12 |

| 5/16 | 6.1 | 6.7 | 7.4 | 0.20 |

| 3/8 | 7.9 | 9.2 | 9.7 | 0.26 |

| 7/16 | 11.8 | 11.9 | 14.4 | 0.38 |

| 1/2 | 13.9 | 15.8 | 16.3 | 0.47 |

| 9/16 | 17.6 | 20.1 | 20.7 | 0.59 |

| 5/8 | 22.8 | 26.0 | 26.6 | 0.77 |

| 3/4 | 31.7 | 36.1 | 37.0 | 1.06 |

| 7/8 | 43.4 | 49.3 | 50.5 | 1.44 |

| 1 | 56.1 | 64.5 | 65.3 | 1.90 |

| 1-1/8 | 71.5 | 82.1 | 83.1 | 2.42 |

| 1-1/4 | 87.4 | 100.9 | 102.2 | 2.97 |

| 1-3/8 | 108.4 | 123.2 | 126.2 | 3.62 |

| 1-1/2 | 127.2 | 144.7 | 148.3 | 4.26 |

| 1-5/8 | 149.3 | 169.7 | 173.9 | 4.97 |

| 1-3/4 | 176.1 | 200.4 | 205.2 | 5.90 |

| 1-7/8 | 197.5 | 224.2 | 229.7 | 6.60 |

| Python® Super 8C | ||||

|---|---|---|---|---|

| Minimum Strength in kN | ||||

| Rope dia. mm | 1770 N/mm² | 1960 N/mm² | 2160 N/mm² | Weight per meter kg |

| 6 | 28 | 31 | 34 | 0.17 |

| 7 | 41 | 45 | 50 | 0.22 |

| 8 | 54 | 60 | 66 | 0.30 |

| 9 | 66 | 73 | 80 | 0.36 |

| 10 | 74 | 85 | 91 | 0.42 |

| 11 | 105 | 106 | 128 | 0.57 |

| 12 | 113 | 129 | 132 | 0.64 |

| 13 | 131 | 150 | 153 | 0.74 |

| 14 | 154 | 175 | 180 | 0.87 |

| 15 | 176 | 200 | 205 | 0.98 |

| 16 | 203 | 231 | 237 | 1.14 |

| 17 | 226 | 257 | 263 | 1.27 |

| 18 | 255 | 290 | 297 | 1.42 |

| 19 | 282 | 321 | 329 | 1.58 |

| 20 | 314 | 357 | 366 | 1.76 |

| 21 | 348 | 396 | 405 | 1.95 |

| 22 | 382 | 434 | 445 | 2.13 |

| 23 | 416 | 473 | 485 | 2.32 |

| 24 | 450 | 512 | 525 | 2.51 |

| 25 | 489 | 556 | 570 | 2.72 |

| 26 | 527 | 600 | 615 | 2.94 |

| 27 | 573 | 651 | 667 | 3.19 |

| 28 | 618 | 703 | 720 | 3.44 |

| 29 | 660 | 751 | 769 | 3.68 |

| 30 | 702 | 798 | 818 | 3.92 |

| 31 | 756 | 860 | 881 | 4.21 |

| 32 | 810 | 921 | 944 | 4.51 |

| 33 | 859 | 977 | 1,001 | 4.80 |

| 34 | 908 | 1,033 | 1,058 | 5.09 |

| 35 | 964 | 1,096 | 1,123 | 5.39 |

| 36 | 1,020 | 1,160 | 1,188 | 5.69 |

| 38 | 1,132 | 1,287 | 1,319 | 6.34 |

| 40 | 1,257 | 1,430 | 1,465 | 7.00 |

| 42 | 1,381 | 1,571 | 1,609 | 7.69 |

| 44 | 1,514 | 1,722 | 1,764 | 8.47 |

| 46 | 1,659 | 1,888 | 1,934 | 9.29 |

| 48 | 1,807 | 2,049 | 2,100 | 10.10 |

|