Python® Ultra

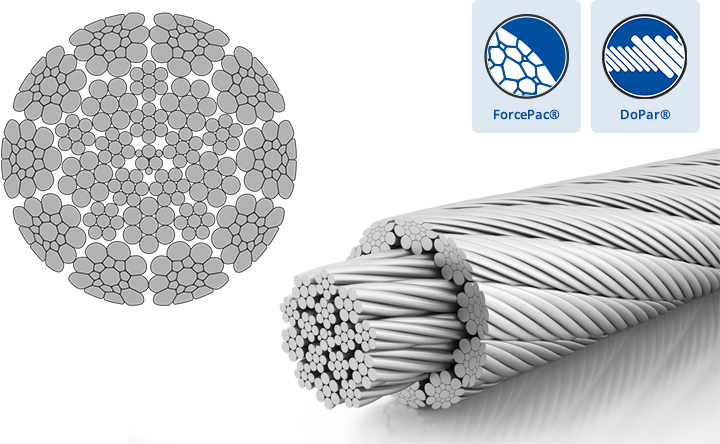

Super high strength for engineered applications (Force Pac® swage compacted)

- 10-strand fatigue resistant ULTRA high strength rope

- ForcePac® compacted design results is highest strength

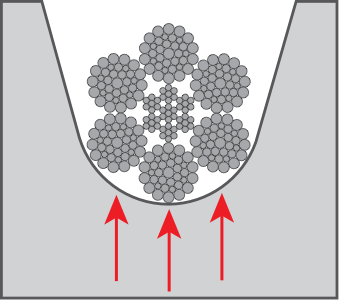

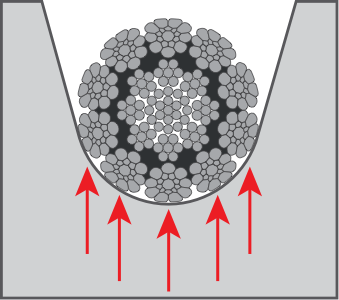

- ForcePac® for lowest sheave contact pressure

- DoPar® Inner strands are laid parallel to the outer strands to avoid any strand cross-overs and premature wire nicking

Main Applications

Super high strength wire rope mainly used for engineered cable assemblies, counterweight ropes, winch lines, boom pendants, extension- and retraction cables, etc. Overhead crane applications for sizes above 3/4″

(19 mm) may require some restrictions as to fleet angle

(max. recommended 2˚) and lay direction.

Call before you select this rope.

Rope Characteristics

Python®-Ultra is our highest strength rope available. It is fully compacted resulting in an extreme smooth outer rope surface and the removal of nearly all of the constructional stretch. This is an important feature if you require a low stretch rope for cables assemblies. Ultra is an ‘all parallel’ construction type, meaning that there are no wire cross-overs within the rope body to ensure maximum fatigue life. Ultra provides a strength increase of up to 53% over regular 6-strand constructions. Refer to the conservatively calculated strength tables.

Python®-Ultra requires corresponding drum grooving directions; e.g. use a right hand lay rope if the drum is left hand grooved. Large fleet angles may cause high strands or core protrusion because the rope will ‘roll’ rather than ‘glide’ into the sheave groove. Any introduction of torque into (any) wire rope will cause structural damages.

| 6-strand | 10-strand | |

|---|---|---|

|

|

Standard

EN 10264, 12385 where applicable

Breaking Strengths

Note: The maximum CAPACITY, WORKING LOAD LIMIT (WLL), or LINE PULL of the rope usually is 1/5 of the below stated values. For specific information consult the standards applicable to your rope application.

| Python® – Ultra | |||

|---|---|---|---|

| Minimum Strength tons of 2,000 lbs | |||

| Rope dia. inch | EIPS | EEIPS | Weight per foot lbs |

| 1/2 | 18.7 | 20.2 | 0.56 |

| 9/16 | 23.4 | 25.4 | 0.73 |

| 5/8 | 28.5 | 32.4 | 0.93 |

| 3/4 | 40.2 | 45.3 | 1.31 |

| 7/8 | 54.6 | 62.4 | 1.75 |

| 1 | 72.6 | 82.7 | 2.25 |

| 1-1/8 | 90.8 | 101.2 | 2.81 |

| 1-1/4 | 113.4 | 124.8 | 3.49 |

| Python® – Ultra | |||

|---|---|---|---|

| Minimum Strength in kN | |||

| Rope dia. mm | 1960 N/mm² | 2160 N/mm² | Weight per meter kg |

| 12 | 143 | 161 | 0.78 |

| 13 | 168 | 190 | 0.91 |

| 14 | 194 | 221 | 1.06 |

| 15 | 223 | 253 | 1.22 |

| 16 | 254 | 288 | 1.38 |

| 17 | 287 | 325 | 1.56 |

| 18 | 321 | 361 | 1.75 |

| 19 | 358 | 403 | 1.95 |

| 20 | 397 | 446 | 2.16 |

| 21 | 438 | 495 | 2.3 |

| 22 | 480 | 545 | 2.57 |

| 23 | 526 | 589 | 2.82 |

| 24 | 571 | 633 | 3.06 |

| 25 | 620 | 688 | 3.33 |

| 26 | 670 | 743 | 3.60 |

| 27 | 724 | 782 | 3.89 |

| 28 | 778 | 857 | 4.17 |

| 29 | 835 | 920 | 4.48 |

| 30 | 893 | 984 | 4.79 |

| 31 | 954 | 1,051 | 5.12 |

| 32 | 1,016 | 1,119 | 5.45 |

|

|