Vectrus™

Rope Characteristics

Vectrus is a single-braid rope of 100% Vectran™ LCP (Liquid Crystal Polymer) and is always treated with Yale’s Maxijacket coating to increase abrasion resistance and enhance the fibers’ UV resistance. LCP is more tolerant of tighter bending radii in terminations than other high-modulus fibers.

Breaking Strengths

| Diameter (Inches) |

Weight (Lbs/100f) |

Average Spliced Break Strength* (Lbs) |

Minimum Spliced Break Strength* (Lbs) |

Maximum Working Load 5:1** (Lbs) |

|---|---|---|---|---|

| 1/16 | 0.2 | 800 | 720 | 160 |

| 1/8 | 0.4 | 2,790 | 2,511 | 558 |

| 5/32 | 0.9 | 4,820 | 4,338 | 964 |

| 3/16 | 1.2 | 5,600 | 5,040 | 1,120 |

| 1/4 | 1.9 | 8,200 | 7,380 | 1,640 |

| 5/16 | 2.8 | 16,260 | 14,634 | 3,252 |

| 3/8 | 4.0 | 19,470 | 17,523 | 3,894 |

| 7/16 | 5.5 | 26,390 | 23,571 | 5,278 |

| 1/2 | 7.5 | 32,000 | 28,800 | 6,400 |

| 9/16 | 10.0 | 38,000 | 34,200 | 7,600 |

| 5/8 | 12.7 | 52,500 | 47,250 | 10,500 |

| 3/4 | 19.4 | 70,000 | 63,000 | 14,000 |

| 7/8 | 24.5 | 89,000 | 80,100 | 17,800 |

| 1 | 31.1 | 109,000 | 98,100 | 21,800 |

| 1-1/4 | 46.1 | 147,000 | 132,300 | 29,400 |

| 1-3/8 | 58.4 | 187,000 | 168,300 | 37,400 |

| 1-1/2 | 67.9 | 210,000 | 189,000 | 42,000 |

| 1-5/8 | 79.9 | 245,000 | 220,500 | 49,000 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

| Diameter (mm) |

Weight (Kg/100m) |

Average Spliced Break Strength* (kg) |

Minimum Spliced Break Strength* (kg) |

Maximum Working Load 5:1** (kg) |

|---|---|---|---|---|

| 2 | 0.3 | 360 | 324 | 72 |

| 3 | 0.6 | 1,265 | 1,139 | 253 |

| 4 | 1.3 | 2,185 | 1,967 | 437 |

| 5 | 1.8 | 2,540 | 2,286 | 508 |

| 6 | 2.8 | 3,720 | 3,348 | 744 |

| 8 | 4.2 | 7,380 | 6,642 | 1,476 |

| 10 | 6.0 | 8,835 | 7,952 | 1,767 |

| 11 | 8.2 | 11,980 | 10,782 | 2,396 |

| 13 | 11.2 | 14,525 | 13,073 | 2,905 |

| 14 | 14.9 | 17,250 | 15,525 | 3,450 |

| 16 | 18.8 | 23,835 | 21,452 | 4,767 |

| 19 | 28.9 | 31,780 | 28,602 | 6,356 |

| 22 | 36.5 | 40,405 | 36,365 | 8,081 |

| 25 | 46.4 | 49,485 | 44,537 | 9,897 |

| 32 | 68.6 | 66,735 | 60,062 | 13,347 |

| 35 | 87.0 | 84,895 | 76,406 | 16,979 |

| 38 | 101.1 | 95,340 | 85,806 | 19,068 |

| 41 | 119.0 | 111,230 | 100,107 | 22,246 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

||||

Rope Details

Rope Benefits

|

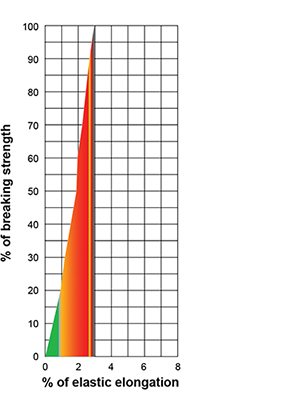

Elastic ElongationThe coloured area under the curve represents the rope’s energy absorption capability.

|