Twin-Path® Slings Information

Twin-Path®

|

|

Twin-Path® Extra

|

| Strongest and lightest lifting sling in the world | |

| Built-in Early Warning Check-Fast® (EWI) System | |

| Double paths means double safety | |

|

Cover made from extra thick bulked CoverMax® fabric |

Twin-Path® Sparkeater

TPSE

Sparkeater slings are made from 100% Aramid load yarns protected by a DOUBLE cover made from Nomex® flame resistant fabric. If you have a hot environment up to 150°C (300°F) use a Twin-Path® Sparkeater to lift the load without marring the surface. Ideal for welding shops and as black coloured suspension sling for stage riggers.

| 100% Aramid load yarns | |

| 100% Nomex® DOUBLE covers | |

| Available in YELLOW for welding shops. | |

| Built-in Early Warning Check-Fast® (EWI) System |

TWIN-PATH®: The Advantages |

||

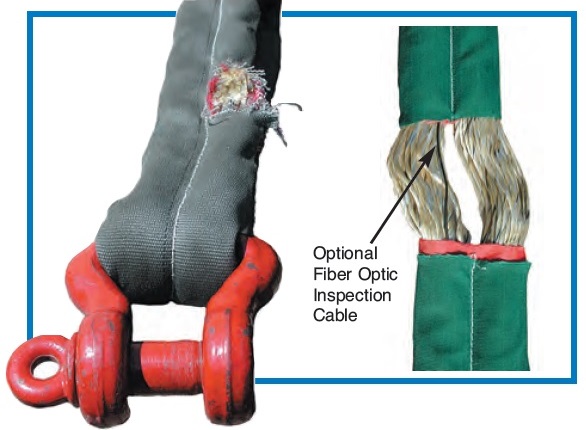

Twin-Path® Slings are actually two complete slings in one. This unique back-up protection provides 2 independent paths to connect the load to the crane hook or fitting. If one path is damaged in use, the second path will perform as a back-up until the load is lowered. Each path alone is as strong as at least 2-1/2 times of the total sling capacity. Twin-Path® helps reduce the potential of catastrophic material mishandling. We don’t recommend the abuse in the above picture but if damage occurred to your Twin-Path® Sling, chances are good that you could still maintain control of the load. |

Double layered, colour contrasted independent covers provide extra protection and early warning. If the inner red cover is visible the sling has been damaged. If the red cover or inner load bearing yarns are visible, remove the sling from service and send it to Unirope® for inspection and possible repair. |

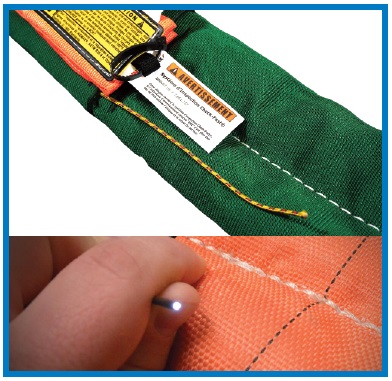

Overload Indicators (Check✓Fast™) and optional Fiber Optic Cables make it easy for inspection. The patented early warning Indicator (EWI) system installed in one path, yellow-red, provides easy pass/fail inspection. Damage to the core yarn from abrasion, fatigue, and severe overload can be detected. If the sling is mistakenly overloaded the EWI is designed to disappear before the sling fails. The EWI can be combined with the optional Fiber Optic Cable. |

|

GUESS which sling required less effort to rig, has less chance of causing injury, is easiest to transport and store, and costs less to use ? Each sling has a rated capacity of 50 tons ! Each person is holding the same weight ! Each sling is the same length ! Which Sling would you use to lift 50 tons ? WIRE ROPE – 400 lbs.  POLYESTER ROUND – 200 lbs. |

TWIN-PATH® EXTRA – 44 lbs. |