Wire Mesh Slings

- Mesh is made from 304 Stainless steel

- Corrosion Resistant

- Cross Rods WELDED to Spirals

- Each sling comes Proof Tested to 2 x WLL

- Maximum Operating Temperature 550˚F

- Slings comply with ASME B30.9-3

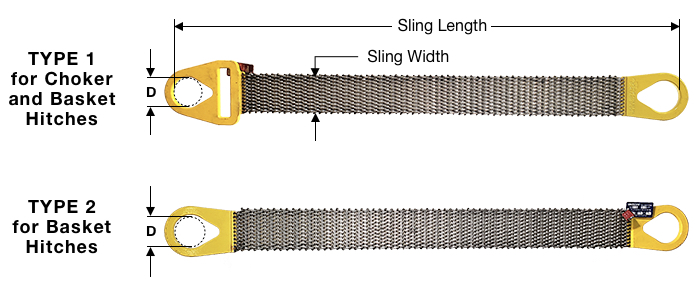

Type 1 TC, for Choker and Basket

|

Type 2 TT, for Basket Hitches

|

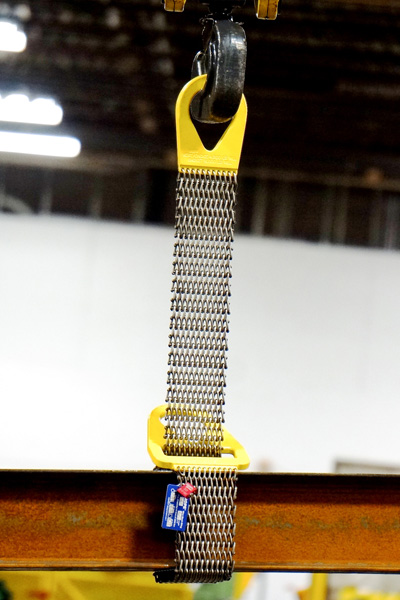

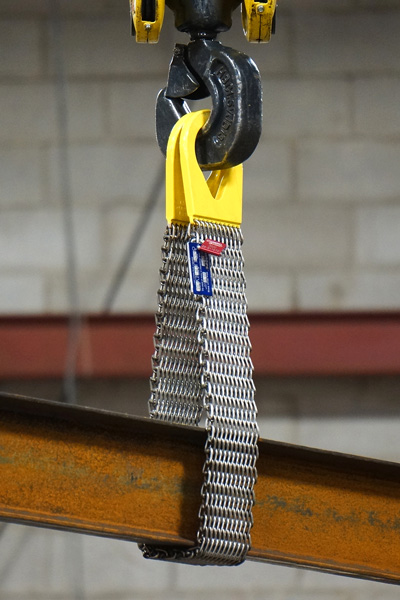

Each Sling comes with a durable marked Capacity Tag and a colour coded serial number Bar-Loc showing year of last Inspection and Proof Test Certification. Each sling is entered into Unirope’s FIELDID Asset Management System for you to access at any time. |

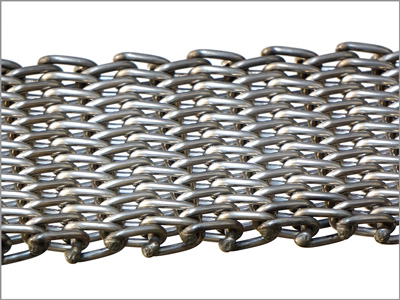

Heavy Duty 304 Stainless Steel Wire Mesh, made super strong with cross rods WELDED to spirals. |

Working Load Limit lbs (Design Factor 5:1)

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Product Code for Type 1 | Product Code for Type 2 | Sling Width | D inch |

Sling weight 3 ft incl. Fittings lbs(1) |

Add for each ft of sling length lbs |

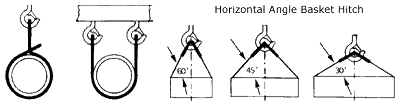

Choker (1) | 90° Basket | 60° | 45° | 30° |

| WMS-304-UR-02-C | WMS-304-UR-02-B | 2 | 2.00 | 5.9 | 1.17 | 2,300 | 4,600 | 3,990 | 3,250 | 2,300 |

| WMS-304-UR-03-C | WMS-304-UR-03-B | 3 | 2.50 | 8.9 | 1.84 | 3,500 | 7,000 | 6,050 | 4,950 | 3,500 |

| WMS-304-UR-04-C | WMS-304-UR-04-B | 4 | 3.00 | 11.4 | 2.58 | 4,800 | 9,600 | 8,300 | 6,750 | 4,800 |

| WMS-304-UR-06-C | WMS-304-UR-06-B | 6 | 3.50 | 17.2 | 3.95 | 7,200 | 14,400 | 12,250 | 10,180 | 7,200 |

| WMS-304-UR-08-C | WMS-304-UR-08-B | 8 | 4.50 | 25.1 | 5.28 | 9,600 | 19,200 | 16,650 | 13,570 | 9,600 |

| WMS-304-UR-10-C | WMS-304-UR-10-B | 10 | 4.75 | 30.4 | 6.50 | 12,000 | 24,000 | 20,800 | 16,970 | 12,000 |

| WMS-304-UR-12-C | WMS-304-UR-12-B | 12 | 5.00 | 44.8 | 7.80 | 14,400 | 28,000 | 24,250 | 19,800 | 14,400 |

|

(1) Applies to Type 1 slings ONLY. |

||||||||||