Web Sling Inspection and Removal Criteria

Inspection of Slings

A specific procedure for the inspection of synthetic slings is your best safeguard against sling damage and abuse. We recommend that you employ a three stage level of inspection as outlined in ASME B30.9. Note that there are no Canadian Standards for slings however, some Provinces and Ministries of Labour have issued specific inspection and removal criteria depending on where the slings are used (construction or industrial use). Consult your local authorities. In Ontario consult the O.H.S.A. Another source of information is the CSAO, Construction Safety Association of Ontario.

Initial Inspection

This inspection is done at the time the product is first received to ensure that damage has not occurred during shipment. Also verify that the goods are in compliance with the specification of the purchase order.

Frequent Inspection

This level of visual inspection should be done by the person handling the sling, or other specifically designated personnel. Records are not required.

- Normal service – daily when in use

- Severe service – each use

- Special or infrequent service – as recommended by a qualified person before and after each use.

Periodic Inspection

The periodic level of inspection is done by designated personnel at regular intervals. The interval is based upon the frequency of use, severity of service conditions, and information derived through the inspection process. Recommendations to prevent damage must be evaluated to improve the service life of the replacement slings. Written records must be kept.

Web Sling Inspection

(Note that for educational and graphic purposes these examples are overly explicit. In service remove for much less obvious or less explicit damages)

Broken or worn stitching

Rips and snags

Crushed webbing

Missing or elligible Tags

Cuts and abrasion

Snags and damage to the edges

Weld splatter

Embedded materials

Localized heat/open flame damage

Knots

Surface abrasion

Damaged eye

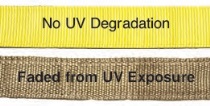

UV Degradation

Cuts

Tensile Break