Tech-Flash

Synthetic Sling Protection

Posted: November 12, 2024One of the leading causes of sling failure and load drop is from inadequate sling cut protection. We offer an extensive range of cut protection from simple Protec™ Wear Pads including our Protec Ballistic™ Body Armor up to CornerMax® Sleeves and and CornerMax® Pads.

Read More...The Importance of Proof Testing

Posted: August 23, 2024The importance of proof testing after a visual inspection. Above is a picture of a 1inch diameter 2-leg Gr 80 chain sling where a welded link was used to connect the eye to the sling hook. The welded link broke and stretched just below the 94,000 lbs. Proof Load.

Read More...To Swivel or Not to Swivel?

Posted: February 5, 2024You may already use so called ‘swivel’ hooks. But did you know that ‘standard’ swivel hooks do NOT swivel when loaded? These hooks do NOT have a thrust bearing but the load nut sits directly on the hook support.

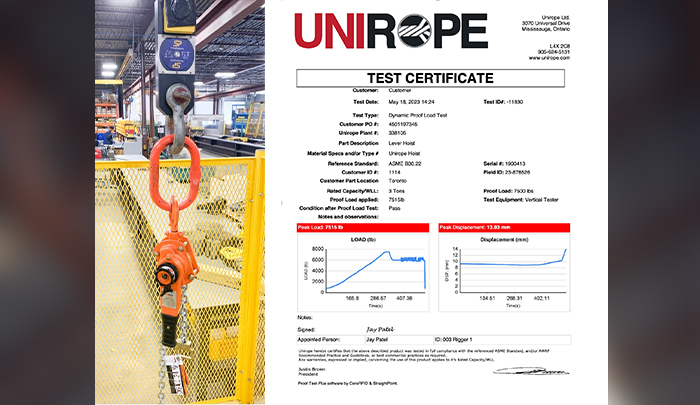

Read More...Are Your Hoists Dynamically Proof-tested?

Posted: December 15, 2023What is a ‘dynamic’ proof test? This is when the hoist is not only loaded once to a proof load (usually between 100% and 120% of Rated Hoist Capacity) but chain travel during this test should result in at least a minimum of one full rotation of the chain sprocket.

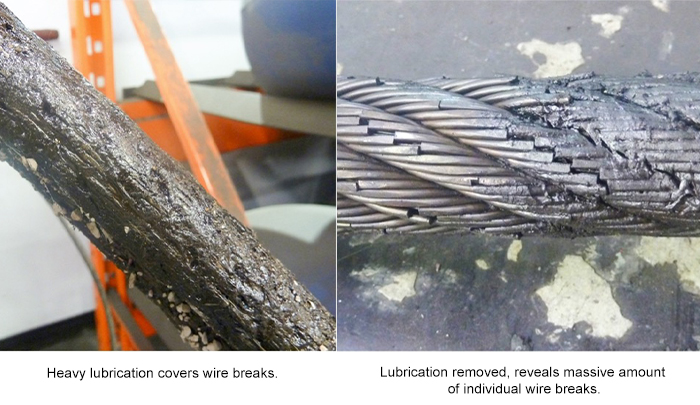

Read More...Too Much Lubrication Prevents Rope Inspection

Posted: November 24, 2023During manufacturing, wire rope is lubricated to reduce internal and external frictions. Tests performed by the University of Stuttgart, Germany, have shown that non-lubricated ropes will only last 1/3 of well lubricated ones.

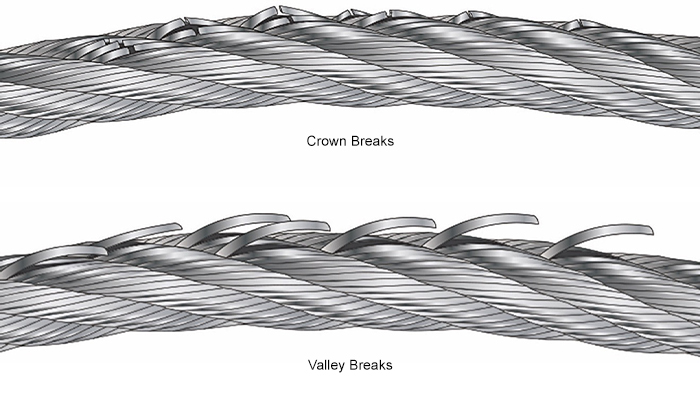

Read More...Overlooked Rope Inspection Details?

Posted: October 30, 2023When inspecting wire rope, it is crucial that you know the difference between Crown and Valley breaks. Crown breaks originate at the OUTSIDE of the rope and are mainly caused by the interaction between the rope and sheave or drum.

Read More...Why Rigging Hardware Must “Stretch”

Posted: March 31, 2023One of the most important features of quality rigging hardware is the ability to stretch when overloaded. This ductility is a design feature and warning that your rigging is about to fail.

Read More...Safety Spotlight

Posted: March 6, 2023Safe Rigging Starts Here.

Yes, it starts with that must know and can easily read the rated lifting capacity of your slings. Sling tagging has long been a problem within the industry. Either they were made from steel plate with hard to read stamped in numbers, or they were skimpy and small.