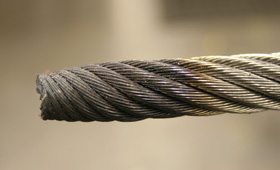

Fused and Tapered Rope Ends

This method ensures that the rope ends will not ‘unravel’ or ‘flare open’ when the rope is installed or handled.

The Fusing and Tapering method is also welcomed by anyone who has to install ropes into wedge sockets or who has to re-reeve hoisting ropes on a mobile crane.

All non-rotating rope ends are dipped in a red plastic powder. There is no real technical reason for it other than that you can find the rope end much easier while re-configurating the number of line parts in your hoisting block.

This end preparation is FREE OF CHARGE for the following rope: Python® Lift, Compac 35, Compac 18, Hoist, Multi, Super 8, Classic 8, Power 9, Ultra, Uni 4, 19×7, 24×7, 19×19, all 8-strand ropes as well as all DoPar types.

Interested in how it’s done?

Here are a few pictures describing the method:

|

|

| This is a weld- and taper machine. Basically, it clamps the rope between two conductors while one end (where the hand wheel is) can be rotated… | …and passes electric current between the conductors and through the rope… |

|

|

| …while we are totating one side of the conductor and pulling on them sideways to increase the distance between them… | …and, voila, we are done! |